|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

Smoking

Shelter/Bus Stop Prices |

|

|

Model

No. |

Usable

Size (W x D x H) |

Overall

Size (W x D x H) |

Net

Weight |

Price |

|

69

3/4" x 37 1/2" x 77" |

77"

x 50" x 84" |

490

lbs |

$2,587.38 |

|

1

Anchor Bolts for Concrete 3/8" x 3" |

1

lbs |

$11.23 |

|

4

Anchor Bolts for Concrete 3/8" x 3" |

4

lbs |

$16.23 |

|

|

|

|

|

Assembly

Instructions for the Smoking Shed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

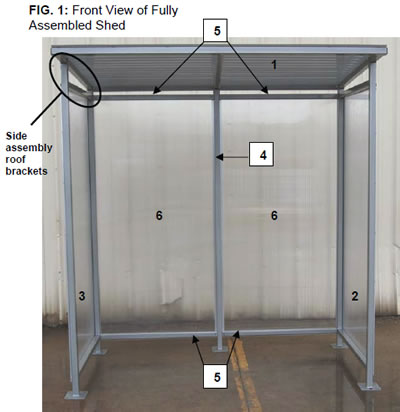

| Number |

Description |

Quantity |

| 1 |

Roof Assembly |

1 |

| 2 |

Right Side Assembly* |

1 |

| 3 |

Left Side Assembly* |

1 |

| 4 |

Vertical Support |

1 |

| 5 |

Horizontal Support |

4 |

| 6 |

Plastic Panel |

2 |

| 7 |

Single-Sided Panel Brackets |

2 |

| 8 |

Double-Sided Panel Bracket |

1 |

| 9 |

Panel Top Bracket |

2 |

| 10 |

5/16 x 2-1/4 inch Roof Fastening Bolt |

5 |

| 11 |

5/16 inch Nylock Nut |

5 |

| 12 |

#12 x 7/8 inch LG Tek Screw |

29 |

| 13 |

#12 x 1-1/4 inch LG Tek Screw |

6 |

| 14 |

Rubber-backed washer |

6 |

| 15 |

Flat Washer |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

*Note: The

side assemblies are named "left" and

"right" from the perspective of a person standing

in front of the shelter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

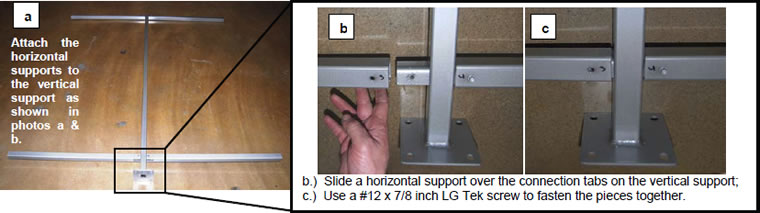

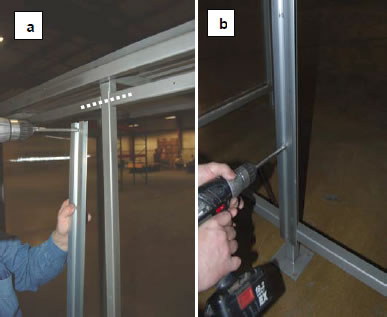

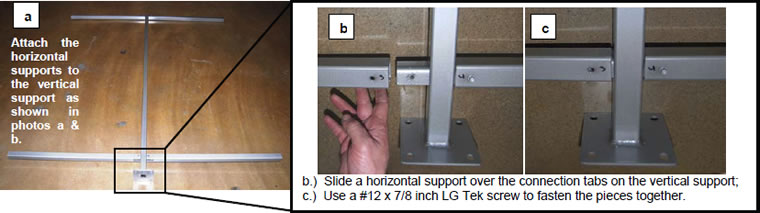

| Step

1: Assemble the supporting framework for the plastic

panels. |

|

|

|

|

|

|

|

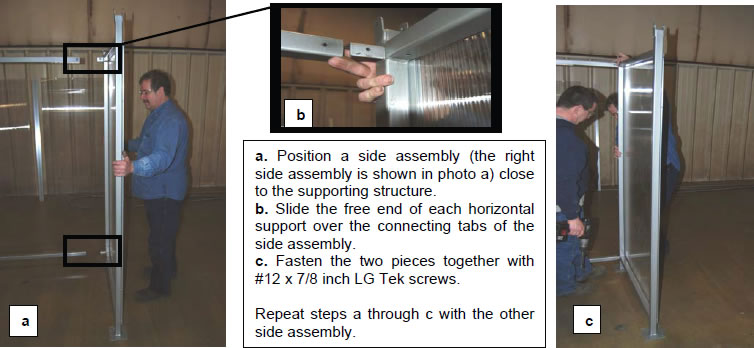

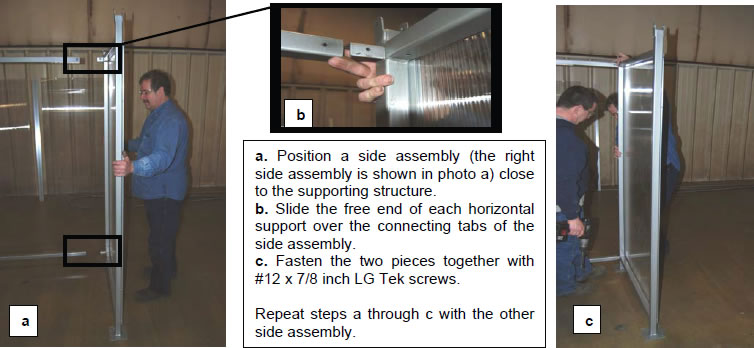

| Step

2: Attach the supporting framework to each of

the side assemblies. |

|

|

|

|

|

|

|

|

|

| Step

3: Attach the roof assembly. |

|

|

|

|

|

a)

Each side of the roof

assembly includes

bracket holes. Notice

that the rear bracket

hole is positioned

close to an end, while

the front bracket hole

is inset ~8-10 inches

from the front edge

of the roof.

b) Set the roof

assembly into

the roof brackets.

c) Fasten the roof

assembly to each

roof bracket with a

2-1/4 inch bolt.

Tighten a nylock nut

onto each bolt. |

|

|

|

|

|

|

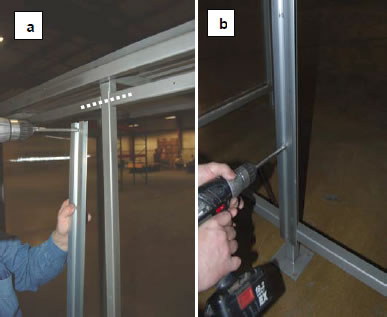

| Step

4: Attach double-sided bracket to the vertical

support. |

a)

Drill holes in the center portion of the double-sided

bracket. Drill a hole approximately 1 inch from

each

end. Drill 5 more holes evenly spaced between the

top and bottom holes. Clamp the bracket to the

vertical support so that the top of the bracket

aligns

with the dotted line shown in photo a (approx. 1-1/4

inch from the top of the horizontal support). Drill

holes in the vertical support that match the holes

you just drilled in the bracket. Start a #12 x 7/8

inch

LG Tek Screw in the top hole of the double-sided

bracket. Match the end of the screw with the top

hole in the vertical support.

b) Place a #12 x 7/8 inch LG Tek Screw in each of the remaining

holes. |

|

|

|

|

|

Note: Installing the plastic panels may require some

looseness in the connection between the vertical

support and the double-sided bracket. |

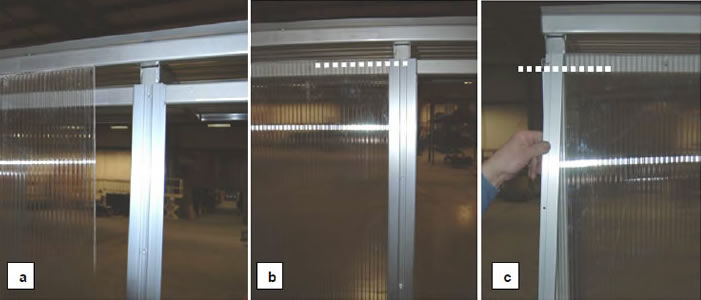

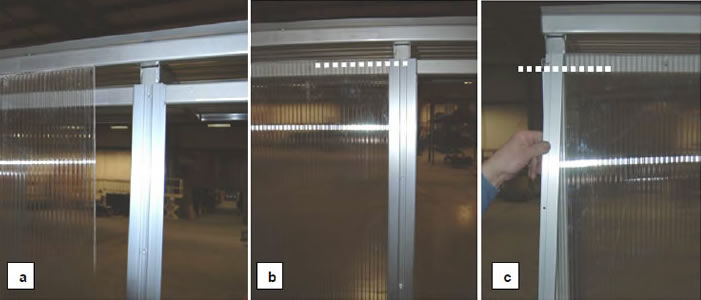

| Step

5: Install the plastic panels. |

|

|

|

|

|

|

|

|

|

|

|

|

a

& b) Slide a plastic panel into the right side

of the double-sided bracket. Notice that

each panel is covered by a thin sheet of

plastic. The protective covering will

indicate which side of a panel is the

exterior. Remove the plastic covering from

both sides of each panel. Insert the panel

into the bracket with the exterior side

facing outwards. Line up the top of the

panel with the dashed white line shown in

photo b.

c) Slide a single-sided panel bracket onto the

free end of the panel. Align the top of the

bracket with the bottom of the horizontal

support (dotted line).

d) Tap the single-sided panel bracket onto the

panel to ensure a secure connection. Clamp

the bracket to the side assembly. Drill a

hole at each end of the bracket and inset

them approximately 1 inch. Drill through

the bracket and into the side assembly.

e) Fasten the bracket to the side assembly

using #12 x 7/8 inch Tek screws.

f) Connect the bottom of the panel to the

horizontal support. Drill 3 evenly-spaced

holes through each of the panels and into

the horizontal support behind it. Wind a rubber-backed

washer onto a 3/4 inch #10 Tek screw, and then slide a

flat washer onto

the screw, and then fasten the panel to the

horizontal support.

g) Slide the top bracket over the top of

the panel. |

|

|

|

|

|

Step

6: Repeat Step 5 a through g with the other panel.

If you had to

loosen the screws holding the double-sided bracket to the vertical

support (Step 4), retighten the connections. |

|

|

|

|

|

Smoking Enclosure, Smoking

Enclosures, Smoking Shelter, Smoking Shelters, Bus Stop, Bus Stops, Transit

Shelter, and Transit

Shelters from your complete source for material handling equipment. |

Back

to Product Category |

|

|