|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Price of the item you wish to purchase. |

|

|

|

|

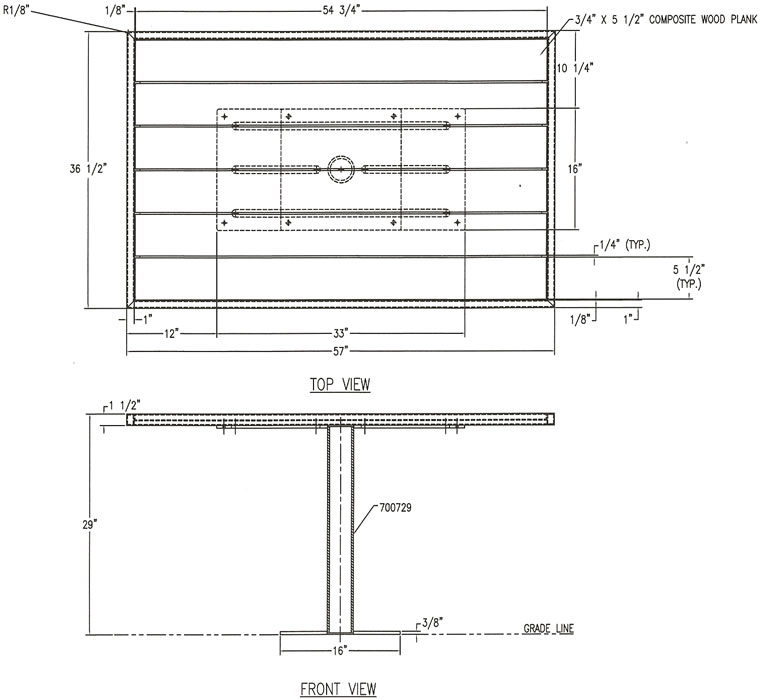

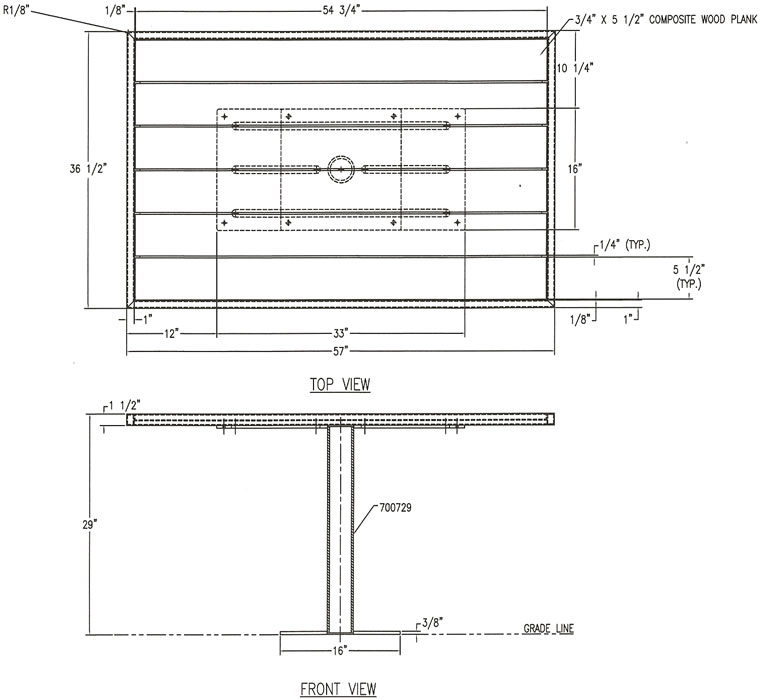

Aluminum

powder coated table frames

with recycled plastic lumber slats.

Galvanized steel center posts available

in a variety of mounting options, with

or without umbrella holes. Choose the

color for both the top and legs. Matching

chairs and benches available. Assembly

& anchoring required.

Size: 57” x 36” x 29”

Weight: 180 Lbs.

Material: Steel, Aluminum, Wood

Special Features: Surface mount

Hardware: Hardware kit (400255)

*Assembly required. ADA Compliant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model: 1037

Price: $1,166.20 |

|

|

|

|

|

COLORS

FOR PANEL |

|

|

|

|

|

COLORS

FOR FRAME |

|

|

|

|

|

TECHNICAL

INFORMATION - POWDURA® Epoxy Powder Coating |

|

PRODUCT

DESCRIPTION

EAS6-00025

ZINC RICH PRIMER

POWDURA® Epoxy Powder Coating is recommended for a broad range

of interior functional and

decorative applications.

APPLICATION

Cure Schedule: 10 min @ 205°C (401°F)

Film Thickness Range: 1.5-1.8 mils

ATTRIBUTES

Specific Gravity: 2.83 +/-0.05

Coverage at 1.0 mil: 67.8 sq.ft/lb

60 Gloss: Visual

Adhesion: No Failure with 1/16in. squares(5B) (ASTM D-3359)

Flexibility: Pass 1/8" Mandrel Bend (ASTM D-522)

Pencil Hardness: H-2H (ASTM D-3363)

Impact Resistance(dir/rev): 160/160 (ASTM D-2794)

Other Notes

SaltSpray Performance: When top coated with TGIC polyesters,urethanes

and fluoroploymers, testing showed

4-5 mm undercut at 5000 hours on Bonderite 1000

Storage:

POWDURA® Powder Coatings should be kept in a dry and cool area at

temperatures below 80°F (26.7° C).

Shelf life is approximately 12 months.

When not in use, store powder in sealed containers: fine powders are hygroscopic.

Substrate Preparation

General: Substrate should be free of grease, oil, dirt, fingerprints,

drawing compounds, any contamination, and

surface preparation treatments to ensure optimum adhesion and coating

performance properties. The use of a

chemical conversion coating prior to the application of a powder coating

is strongly recommended. Consult Metal

Preparation Brochure CC-T1 for additional details.

Aluminum: A minimum of a 5-stage chrome phosphate metal treatment, or

equivalent, is required for good adhesion

and optimum coating performance properties.

Testing:

Due to the wide variety of substrates, surface preparation methods, application

methods, and environments,

the customer should test the complete system for adhesion and compatibility

prior to full-scale application.

The properties listed are typical and should not be construed as the actual

specification.

Product Limitations:

Contact your Sherwin-Williams Representative where use of this product

at higher than recommended film

thickness may be required.

APPLICATION:

Powder coatings must be applied using suitable electrostatic equipment.

Consult your Sherwin-Williams

Representative regarding unique applications.

CAUTIONS:

Thoroughly review product label for safety and cautions prior to using

this product. Please direct any questions

or comments to your local Sherwin-Williams facility.

CAUTION! Causes eye irritation, causes skin irritation, may cause

allergic skin reaction, respiratory irritant, dust

may cause eye and respiratory irritation, dust may form an explosive mixture

in air. Avoid breathing dust. Avoid

contact with eyes and prolonged or repeated contact with skin. Use protective

clothing and NIOSH approved

respirator. Do not use near sparks or open flame or any type of ignition

source. Wash thoroughly after handling.

Use only with adequate ventilation.

FIRST AID:

If on SKIN: Wash thoroughly with soap and water.

If in EYES: Flush with water immediately and procure medical attention.

The area adjacent to the coating operation

should be properly ventilated. Cure ovens must be exhausted to the outside

atmosphere. All dusts are respiratory

irritants, inhalation of the dust should be avoided. To avoid static electricity

buildup, properly ground all equipment.

Provide dust collection equipment with adequate explosion venting; dust

clouds of any finely divided organic material

can be ignited by open flame or electrical sparks.

DO NOT TAKE INTERNALLY. KEEP OUT OF REACH OF CHILDREN. FOR INDUSTRIAL

USE

ONLY. REFER TO MATERIAL SAFETY DATA SHEET FOR ADDITIONAL INFORMATION.

Note:

Product Data Sheets are periodically updated to reflect new information

relating to the product. It is important that

the customer obtain the most recent Product Data Sheet for the product

being used. The information, rating and

opinions stated above pertain to the material currently offered and represent

the results of tests believed to be reliable.

However, due to variations in customer handling and methods of application

which are not known or under our

control, The Sherwin-Williams Company cannot make any warranties or guaranties

as to the end results. |

|

HYPEL™

LLDPE 3170 UV 8 NATURAL ** LINEAR LOW DENSITY POLYETHYLENE, 7.0 MFI |

|

TYPICAL

PROPERTY VALUES† |

|

PROPERTY |

METHOD |

UNIT |

VALUE |

PHYSICAL |

Specific

Gravity |

ASTM

D792 |

|

0.935 |

Metal

flow (190°C / 2.16 kg) |

ASTM

D1238 |

g/10

min |

7 |

MECHANICAL

@ 73°F |

Tensile

Strength at Yield |

ASTM

D638 |

psi |

2720 |

MPa |

18.8 |

Flexural

Modulus - 1% Secant |

ASTM

D790 |

psi |

100,000 |

MPa |

655 |

ARM

Impact 1/8" (Notched) @-40°C |

ASTM

D562B |

ft-LB/in |

79 |

Hardness

(Shore D) |

ASTM

D785 |

- |

- |

THERMAL |

264

psi - ASTM, 1.80 MPa-ISO |

ASTM

D648 |

°C |

35 |

°F |

95 |

66

psi - ASTM, 0.45 MPa-ISO |

ASTM

D648 |

°C |

52 |

°F |

125 |

OTHER |

ESCR

(100% IGEPAL) |

|

|

>1000 |

|

|

**When

used unmodified for food contact applications, this copolymer will comply

with the U.S. Food and Drug

Administration Food Additive Regulation 21 CFR 177.1520(c)3.1a. This section

does not include use in packing

or holding food during cooking. This product is limited to use in contact

with food only under the conditions of use

C through H described in table 2 of Sec. 176.170(c), and when contacting

fatty foods of Types III, IVA, V, VII-A,

and IX described in table 1 of Sec. 176.170(c), the finished articles are

to have a volume of at least 18.9 liters (5

gallons). The uses cited are subject to good manufacturing practices and

any limitations, which are part of the regu-

lations. The regulations should be consulted for complete details.

†The data listed here fall within the normal range of product

properties, but they should not be used to establish speci-

fication limits or used alone as a basis for design. This information is

not intended as a warranty of any kind. Buyers

must make their own representative test and assume all risks of use, whether

used alone or in combination with other

products. Entec Polymers, LLC assumes no obligation or liability of any

advice furnished by it or results obtained

with respect to these products. All warranties expressed or implied including

warranties of merchantability for a

particular purpose or use are excluded and disclaimed. Entec Polymers, LLC

assumes no liability for use of products

in infringement of any patent. The foregoing limitation of remedy and exclusion

of liability is reflected in and is part

of the consideration for the price, at which the products are sold by Entec

Polymers, LLC. All data displayed herein

has been obtained via testing of injected molded specimens of natural color.

Pigmentation may affect certain

properties to various degrees. |

|

Lorna Dining Table, Aluminum

Table, Galvanized Steel Tables, In-ground Tables, Polysteel Tables, Recycled

Plastic Tables,

Site Furnishing, Park Tables, Outside Tables, Steel Tables, and Tables

from your source for material handling equipment. |

Back

to Product Category |

|

|