|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

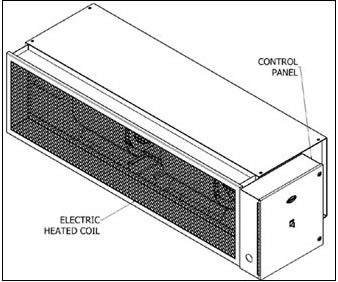

LoPro Commercial Series Air Curtains

Electric Heated

|

The

Most Cost-effective Environmental and Sanitation Barrier You’ll Never

See |

FREE

FREIGHT |

| FOR

ALL AIR CURTAINS SHIPPED TO LOCATIONS WITHIN THE 48 CONTIGUOUS UNITED STATES |

|

|

|

|

|

| The

Most Cost-Effective Environmental and Sanitation Barrier You'll Never See |

|

|

|

| AIR

CURTAIN BENEFITS |

|

LOPRO

COMMERCIAL AIR CURTAINS

SERIES FEATURES |

•

Reduces Energy Costs And Consumption

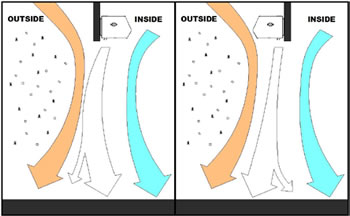

• Creates Effective Environmental Separation

• Maintains Interior Building Temperatures

• Provides Low Operational Costs

• Minimizes Dirt, Dust, And Fumes

• Prevents Flying Insects From Intruding

• Offers An Unobstructed View, Enhancing Safety |

|

|

• Aesthetically

Pleasing “Low Profile” 8" Design

• Low Noise Level For Quiet Operation

• Easy To Install

• Low Maintenance

• NSF Models Available (Contact us.) |

|

|

|

DOOR

HEIGHTS |

|

|

| DOOR

WIDTHS |

|

|

Environmental

Separation up to 8'

Flying Insect Control up to 7' |

| 25"

to 144" |

|

|

|

|

|

|

| HEATING

OPTIONS |

|

|

| Electric

and Steam/Hot Water |

|

|

|

|

|

|

|

|

|

|

|

|

|

Model

No. |

Width

of Door |

Door

Height |

FLA

(Ampacity) Single Phase |

Sound

dBA |

Weight

(lbs) |

115V |

208V/230V |

LPV36 |

36" |

7'

- 8' |

2.4 |

1.2

/1.2 |

49 |

30 |

LPV42 |

42" |

7'

- 8' |

2.4 |

1.2/1.2 |

50 |

33 |

LPV48 |

48" |

7'

- 8' |

2.4 |

1.2/1.2 |

52 |

37 |

LPV60 |

60" |

7'

- 8' |

2.6 |

1.4/1.4 |

53 |

45 |

LPV72 |

72" |

7'

- 8' |

2.6 |

1.4/1.4 |

53 |

56 |

LPV84-2 |

84" |

7'

- 8' |

4.8 |

2.4/2.4 |

53 |

66 |

LPV96-2 |

96" |

7'

- 8' |

4.8 |

2.4/2.4 |

53 |

74 |

LPV108-2 |

108" |

7'

- 8' |

5 |

2.6/2.6 |

54 |

82 |

LPV120-2 |

144" |

7'

- 8' |

5.2 |

2.6/2.6 |

54 |

90 |

LPV144-2 |

144" |

7'

- 8' |

5.2 |

2.8/2.8 |

54 |

112 |

|

|

LOPRO

(LPV) 1/6 HP VARIABLE SPEED ELECTRIC

HEATED

COMMERCIAL MODELS

|

|

|

|

|

|

|

|

NOTES: |

|

1. This

product is designed to meet the

National Electric Code (NEC) and is ETL

Listed for the US and Canada. |

|

2. Continuous

duty, direct drive, variable

speed, double shaft motors with automatic

thermal overload protection. Overload

protects motor from burnout, minimizing

maintenance costs. |

|

3. Blower

wheels are rust proof and

dynamically balanced to provide quiet

operation, while maintaining high air velocity. |

|

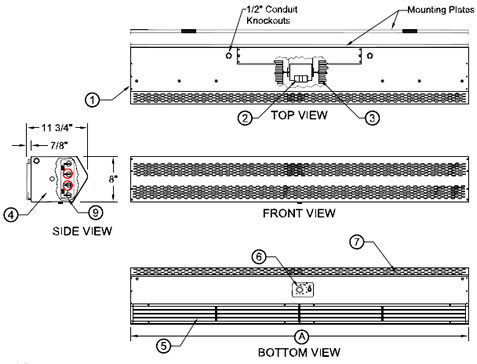

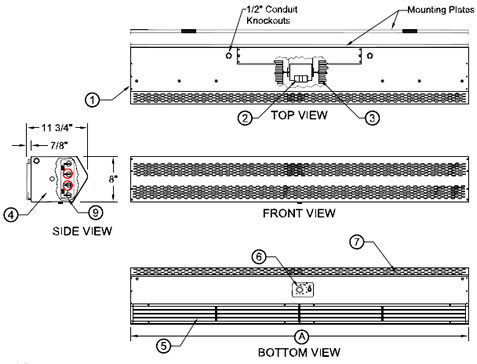

4. Low

profile appearance. Overall height is

8" and overall depth is 11 3/4". |

|

5. Air

directional vanes, with 40° sweep front

to back, compensates for drafts. |

|

6. Mounted

adjustable speed controller knob

allows air velocity to meet a wide range of

field conditions. Units greater than 72" are

double units joined with a 2" mounting

bracket located in the center, field installed.

The speed controller will be located on the

right hand unit and controls both units. |

|

7.

All units have a self contained one piece

cabinet, fire retardant and corrosion proof

point lock metal, double protected with

Obsidian Black rust preventative electro-

static powder coating . |

|

|

|

|

|

|

|

|

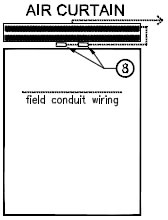

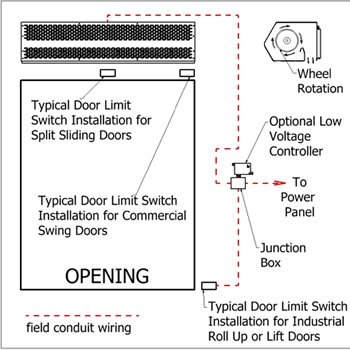

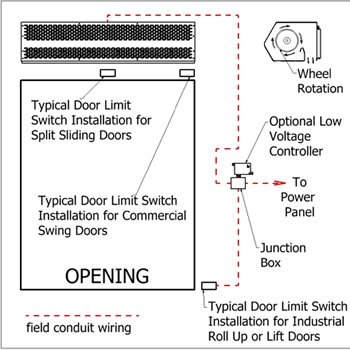

8.

Normally closed door limit switch(es) is

optional and field installed. Switch to be

mounted so the air curtain turns on

as the door begins to open. |

|

|

|

|

|

|

|

9.

Units greater than 72" require dual power

supplies, one for each air curtain. |

|

|

|

|

|

| Model No. |

Unit Length

(A) |

| LPV236-1E |

36" |

| LPV242-1E |

42" |

| LPV248-1E |

48" |

| LPV260-1E |

60" |

| LPV272-1E |

72" |

| LPV284-2E |

86" |

| LPV296-2E |

98" |

| LPV2108-2E |

110" |

| LPV2120-2E |

122" |

| LPV2144-2E |

146" |

|

|

|

|

TYPICAL

INSTALLATION |

|

|

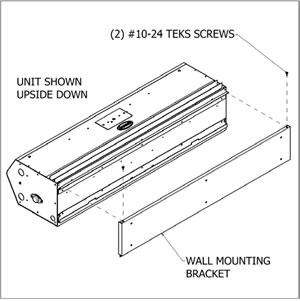

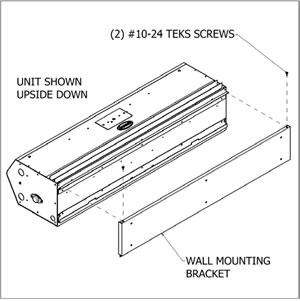

1- lnstall Mounting

plate(s) using the pre-drilled

holes. |

|

|

2 - Securely attach

cabinet to mounting plate

using tabs as guides, when fully inserted

secure with (2) #10 Tek Screws.

"CAUTION": Unit

to be mounted with

the lowest moving part at least 7 Feet above

floor or grade level. |

|

|

3 - lnstall optional

door limit switch(es) to door

header. (8) |

|

|

4

- Connect internal wires from unit to supply

power. |

|

|

|

|

|

|

|

|

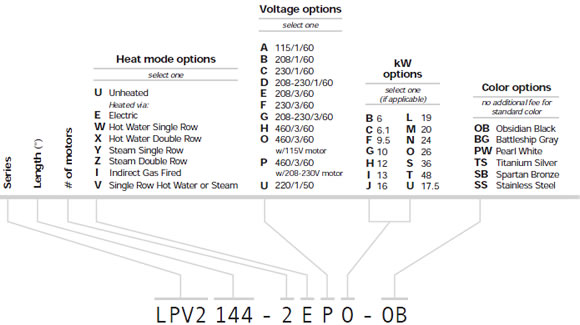

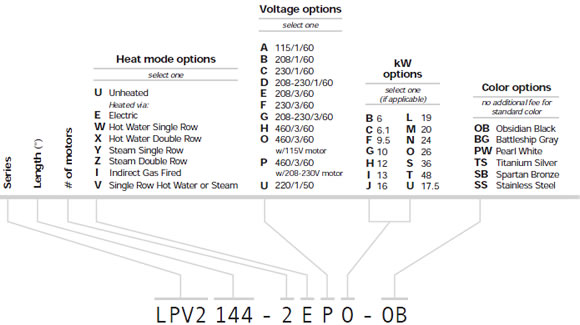

Understanding

Series Order Codes |

|

|

| Standard

Features: |

|

|

| •

Easy Install Mounting Plate |

|

| •

18 month warranty |

|

| •

1/6 HP Direct Drive |

|

| •

Made in USA |

|

| •

Variable Speed Controller |

|

|

|

| •

8" Low Profile Metal Design |

Protection |

|

| •

Standard color: |

•

Environmental: 8' |

|

|

|

|

|

•

Flying Insect: 7' |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

PRICING

FOR LOPRO (LPV) VARIABLE SPEED

COMMERCIAL ELECTRIC HEATED MODELS |

Model

No. -

Color

Code (std) |

Voltage |

kW |

Air

Volume

(max.)

| Length |

Height |

Depth |

Full

Load

Draw |

Heater

Draw |

Motor

Draw |

Avg.

Velocity |

Weight

(lbs.) |

Price |

|

208/1/60 |

6.1kW |

900cfm |

36" |

8" |

11

3/4" |

31amps |

~ |

~ |

1800fpm |

35 |

$2,458 |

|

230/1/60 |

6.1kW |

900cfm |

36" |

8" |

11

3/4" |

28amps |

~ |

~ |

1800fpm |

35 |

$2,458 |

|

208/3/60 |

10kW |

900cfm |

36" |

8" |

11

3/4" |

29amps |

~ |

~ |

1800fpm |

35 |

$2,458 |

|

230/3/60 |

10kW |

900cfm |

36" |

8" |

11

3/4" |

26amps |

~ |

~ |

1800fpm |

35 |

$2,458 |

|

460/3/60 |

10kW |

900cfm |

36" |

8" |

11

3/4" |

~ |

13amps |

2.4amps |

1800fpm |

35 |

$2,458 |

|

460/3/60 |

10kW |

900cfm |

36" |

8" |

11

3/4" |

~ |

13amps |

1.2amps |

1800fpm |

35 |

$2,458 |

|

208/1/60 |

8kW |

1050cfm |

42" |

8" |

11

3/4" |

40amps |

~ |

~ |

1800fpm |

40 |

$2,565 |

|

230/1/60 |

8kW |

1050cfm |

42" |

8" |

11

3/4" |

36amps |

~ |

~ |

1800fpm |

40 |

$2,565 |

|

208/3/60 |

10kW |

1050cfm |

42" |

8" |

11

3/4" |

29amps |

~ |

~ |

1800fpm |

40 |

$2,565 |

|

230/3/60 |

10kW |

1050cfm |

42" |

8" |

11

3/4" |

26amps |

~ |

~ |

1800fpm |

40 |

$2,565 |

|

460/3/60 |

10kW |

1050cfm |

42" |

8" |

11

3/4" |

~ |

13amps |

2.4amps |

1800fpm |

40 |

$2,565 |

|

460/3/60 |

10kW |

1050cfm |

42" |

8" |

11

3/4" |

~ |

13amps |

1.2amps |

1800fpm |

40 |

$2,565 |

|

208/1/60 |

8kW |

1200cfm |

48" |

8" |

11

3/4" |

40amps |

~ |

~ |

1800fpm |

45 |

$2,617 |

|

230/1/60 |

8kW |

1200cfm |

48" |

8" |

11

3/4" |

36amps |

~ |

~ |

1800fpm |

45 |

$2,617 |

|

208/3/60 |

13kW |

1200cfm |

48" |

8" |

11

3/4" |

37amps |

~ |

~ |

1800fpm |

45 |

$2,617 |

|

230/3/60 |

13kW |

1200cfm |

48" |

8" |

11

3/4" |

34amps |

~ |

~ |

1800fpm |

45 |

$2,617 |

|

460/3/60 |

13kW |

1200cfm |

48" |

8" |

11

3/4" |

~ |

16amps |

2.4amps |

1800fpm |

45 |

$2,617 |

|

460/3/60 |

13kW |

1200cfm |

48" |

8" |

11

3/4" |

~ |

16amps |

1.2amps |

1800fpm |

45 |

$2,617 |

|

208/1/60 |

9.5kW |

1500cfm |

60" |

8" |

11

3/4" |

47amps |

~ |

~ |

1800fpm |

50 |

$2,688 |

|

230/1/60 |

9.5kW |

1500cfm |

60" |

8" |

11

3/4" |

43amps |

~ |

~ |

1800fpm |

50 |

$2,688 |

|

208/3/60 |

13kW |

1500cfm |

60" |

8" |

11

3/4" |

37amps |

~ |

~ |

1800fpm |

50 |

$2,688 |

|

230/3/60 |

13kW |

1500cfm |

60" |

8" |

11

3/4" |

34amps |

~ |

~ |

1800fpm |

50 |

$2,688 |

|

460/3/60 |

13kW |

1500cfm |

60" |

8" |

11

3/4" |

~ |

16amps |

2.6amps |

1800fpm |

50 |

$2,688 |

|

460/3/60 |

13kW |

1500cfm |

60" |

8" |

11

3/4" |

~ |

16amps |

1.4amps |

1800fpm |

50 |

$2,688 |

|

208/1/60 |

9.5kW |

1800cfm |

72" |

8" |

11

3/4" |

47amps |

~ |

~ |

1800fpm |

56 |

$2,795 |

|

230/1/60 |

9.5kW |

1800cfm |

72" |

8" |

11

3/4" |

43amps |

~ |

~ |

1800fpm |

56 |

$2,795 |

|

208/3/60 |

13kW |

1800cfm |

72" |

8" |

11

3/4" |

37amps |

~ |

~ |

1800fpm |

56 |

$2,795 |

|

230/3/60 |

13kW |

1800cfm |

72" |

8" |

11

3/4" |

34amps |

~ |

~ |

1800fpm |

56 |

$2,795 |

|

460/3/60 |

13kW |

1800cfm |

72" |

8" |

11

3/4" |

~ |

16amps |

2.6amps |

1800fpm |

56 |

$2,795 |

|

460/3/60 |

13kW |

1800cfm |

72" |

8" |

11

3/4" |

~ |

16amps |

1.4amps |

1800fpm |

56 |

$2,795 |

|

Model

No. -

Color

Code (std) |

Voltage |

kW |

Air

Volume

(max.)

| Length |

Height |

Depth |

Full

Load

Draw |

Heater

Draw |

Motor

Draw |

Avg.

Velocity |

Weight

(lbs.) |

Price |

|

208/3/60 |

20kW |

2100cfm

| 84" |

8" |

11

3/4" |

58amps |

~ |

~ |

1800fpm |

76 |

$3,965 |

|

230/3/60 |

20kW |

2100cfm

| 84" |

8" |

11

3/4" |

53amps |

~ |

~ |

1800fpm |

76 |

$3,965 |

|

460/3/60 |

20kW |

2100cfm

| 84" |

8" |

11

3/4" |

~ |

25amps |

4.8amps |

1800fpm |

76 |

$3,965 |

|

460/3/60 |

20kW |

2100cfm

| 84" |

8" |

11

3/4" |

~ |

25amps |

2.4amps |

1800fpm |

76 |

$3,965 |

|

208/3/60 |

26kW |

2400cfm

| 96" |

8" |

11

3/4" |

75amps |

~ |

~ |

1800fpm |

86 |

$4,325 |

|

230/3/60 |

26kW |

2400cfm

| 96" |

8" |

11

3/4" |

68amps |

~ |

~ |

1800fpm |

86 |

$4,325 |

|

460/3/60 |

26kW |

2400cfm

| 96" |

8" |

11

3/4" |

~ |

33amps |

4.8amps |

1800fpm |

86 |

$4,325 |

|

460/3/60 |

26kW |

2400cfm

| 96" |

8" |

11

3/4" |

~ |

33amps |

2.4amps |

1800fpm |

86 |

$4,325 |

|

208/3/60 |

26kW |

2700cfm

| 108" |

8" |

11

3/4" |

75amps |

~ |

~ |

1800fpm |

88 |

$4,686 |

|

230/3/60 |

26kW |

2700cfm

| 108" |

8" |

11

3/4" |

68amps |

~ |

~ |

1800fpm |

88 |

$4,686 |

|

460/3/60 |

26kW |

2700cfm

| 108" |

8" |

11

3/4" |

~ |

33amps |

5amps |

1800fpm |

88 |

$4,686 |

|

460/3/60 |

26kW |

2700cfm

| 108" |

8" |

11

3/4" |

~ |

33amps |

2.6amps |

1800fpm |

88 |

$4,686 |

|

208/3/60 |

26kW |

3000cfm

| 120" |

8" |

11

3/4" |

75amps |

~ |

~ |

1800fpm |

95 |

$5,047 |

|

230/3/60 |

26kW |

3000cfm

| 120" |

8" |

11

3/4" |

68amps |

~ |

~ |

1800fpm |

95 |

$5,047 |

|

460/3/60 |

26kW |

3000cfm

| 120" |

8" |

11

3/4" |

~ |

33amps |

5.2amps |

1800fpm |

95 |

$5,047 |

|

460/3/60 |

26kW |

3000cfm

| 120" |

8" |

11

3/4" |

~ |

33amps |

2.8amps |

1800fpm |

95 |

$5,047 |

|

208/3/60 |

26kW |

3600cfm

| 144" |

8" |

11

3/4" |

75amps |

~ |

~ |

1800fpm |

110 |

$5,407 |

|

230/3/60 |

26kW |

3600cfm

| 144" |

8" |

11

3/4" |

68amps |

~ |

~ |

1800fpm |

110 |

$5,407 |

|

460/3/60 |

26kW |

3600cfm

| 144" |

8" |

11

3/4" |

~ |

33amps |

5.2ams |

1800fpm |

110 |

$5,407 |

|

460/3/60 |

26kW |

3600cfm

| 144" |

8" |

11

3/4" |

~ |

33amps |

2.8amps |

1800fpm |

110 |

$5,407 |

|

Note:

A separate 115v or 208v power source required for motors.

O= 460/8/60, 115/1/60

P= 460/3/60, 208/1/60 |

|

|

|

OB |

|

TS |

|

PW |

|

|

|

|

|

|

|

|

| Optional

Color Available - Std. Production Color is Obsidian Black (matte) See add-on prices below. |

|

|

|

|

|

|

|

Prices

for Colors That are not Standard for the Series

(add these prices to price of Electric Heated

Lopro Comm. air curtain above) |

| Length of Unit |

25" |

36" |

42" |

48" |

60" |

64" |

72" |

84" |

96" |

108" |

120" |

144" |

| TS |

|

|

|

|

|

|

|

|

|

|

|

|

| PW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Part No. of the item you wish to

purchase. |

|

|

|

LOPRO

ACCESSORIES - ELECTRIC HEATEAD |

| DOOR SWITCHES |

| Automatic

on/off control of air curtain as door is opened and closed |

| LINE VOLTAGE |

| Part # |

Package |

Price |

| 99-014 |

Steel Mechanical Universal Surface-Mounted Plunger/Roller Switch |

$141.50 |

| 24 VOLT CONTROL |

| Part # |

Package |

Price |

| 99-018 |

Commercial Magnetic Reed Switch Only Plastic • Surface-mounted

NOTE: Used with control packages J0023 or J0024 for double doors |

$66.10 |

| CONTROL PACKAGES - Combination packages of door switches, controllers,

time delays, and thermostats |

| LINE

VOLTAGE |

| Part # |

Package |

Price |

|

Analog

Thermostat Remote-mounted |

$165.10 |

| FILTERS |

| Part No. |

Filters |

Price |

| FLTR |

Aluminum Mesh Filter 1/4' Internal-mount • Set of 2 • (size):

Specify size in inches |

$3.10/per in. |

|

|

HEATED

PRODUCTS SUPPLEMENT |

|

|

|

|

|

NOTE |

|

Before

proceeding, refer to the units specific IOM Manual for safety, installation

and

start information. Verify proper voltage to the product per local and

NEC codes.

Ensure proper rotation for units with three phase motors. |

|

|

|

|

|

| Electrically

Heated Products |

|

|

|

|

|

|

Electrically

heated products must be mounted on the

inside of the building. Electrically heated products come

standard with a thermostat (provided and shipped loose,

unless ordered as factory pre-mounted) and is to be field

installed. |

|

|

Note:

1. Electrically heated Low Profile units come with internally

mounted controls and available with optional 24 volt

or

240 volt thermostat. |

|

|

2.

Electrically heated Standard, High Velocity and Extra

Power units include a motor control panel mounted on

the right-hand side of the unit, as standard, and a remote

24 volt thermostat with On/Off switch with terminals

provided. |

|

|

|

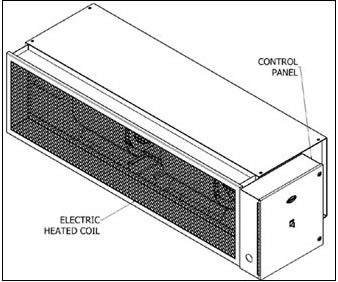

FIG.

1 |

|

3.

Electrically heated Wind Stopping and WindGuard units

include an electric heater control panel mounted on the

right hand side, as standard (FIG. 1). Optional motor/

unit control panel available, which includes a remote

24 volt thermostat with On/Off switch with terminals

provided. |

|

|

|

|

|

|

|

|

|

|

|

The

thermostat should be mounted as close to the

product’s discharge air flow as possible in order to best

sense the discharged air temperature around the door

opening. Connect proper voltage to the product per local

and NEC codes. (FIG. 2) |

|

|

|

|

|

Thermal

overload protection is built into the heater coil

assembly/assemblies. In the event of an overload condition,

electrical power will be disconnected from the heater coil.

Upon diagnosing the problem, electrical power can be re-

instated to the heater coil(s) by manually resetting the

thermal overload lever(s) or buttons(s) located in the unit

or panel. |

|

|

|

FIG. 2 |

|

|

|

|

|

|

|

|

To

operate multiple units mounted side by side, utilizing

a single door switch and single thermostat, a master/slave

configuration is required. (FIG. 2) |

|

|

|

|

LOW

PROFILE (LPV) VARIABLE SPEED AND

LOW PROFILE (LPN) NSF COMMERCIAL SERIES |

|

Installation,

Operation and Maintenance Manual |

Please

read and save these instructions. Read carefully before attempting to assemble,

install, operate or maintain the

product described. Protect yourself and others by observing all safety information.

Failure to comply with these

instructions could result in personal injury and/or property damage. Retain

these instructions for future reference. |

|

|

|

|

|

|

|

| OVERVIEW |

|

|

|

|

|

|

|

|

|

|

|

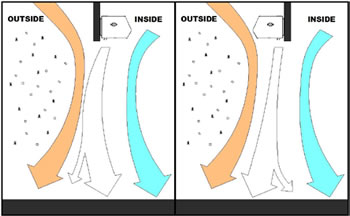

Our

Air Curtains are designed to cover door openings,

providing both temperature control/environmental

separation and flying insect control, when the building’s

doors are opened. Typical installation heights are: LoPro

Series; LPV (Variable Speed) models (Environmental up

to 8’), LPN (NSF for Customer Entrances) models |

|

|

|

|

(Flying Insect Control up

to 7’) and LPN-F (NSF for

Counter Top/Pass Through Windows) models (Flying

Insect Control up to 4’ from Counter Top) All NSF

Certified Models (ETL) should be mounted at the Flying

Insect Control heights referenced above. The units are

typically wall mounted horizontally above the door

opening. They can also be suspended from the ceiling.

The units are ETL Listed, Canada and US, for either an

inside or outside mount and ETL Sanitation Certified.

Heated units must be mounted on the inside or the

protected side of the opening. The motors used in all

LoPro Series are 1/6HP. |

|

|

|

|

|

|

|

|

|

|

WARNING WARNING |

|

To

reduce the risk of fire, electric shock or injury to

persons, observe the following. |

|

A.

Always disconnect, lock and tag power source

before installing or servicing product. |

|

B.

Installation work or electrical wiring must be done

by qualified person(s) in accordance with all ap-

plicable codes and standards, including fire-rated

construction. |

The

LoPro Series come standard with a stamped air intake

screen(s). The LPV models can be configured with an

aluminum mesh filter(s) as an option. The LPN models

25”, 28” and 30” and all LPN-F models come standard

with an aluminum mesh air intake filter(s) in conjunction

with the punched air intake screen(s). |

|

C.

The combustion airflow needed for safe operation

of fuel burning equipment in the area may

be

affected by the product’s operation.

Follow the

heating equipment manufacturer’s guideline

and

safety standards, such as those published

by the

National Fire Protection Agency (NFPA), the

American Society of Heating, Refrigeration

and

Air Conditioning Engineers (ASHRAE) and local

code authorities. |

|

|

|

| GENERAL

SAFETY INFORMATION |

|

|

Use

this product only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer. Only qualified personnel should install

this product. Installing personnel should have a clear

understanding of these instructions and should be

aware of general safety precautions. Improper

installation can result in electric shock, possible injury

due to coming in contact with moving parts, as well as

other potential hazards. |

|

|

|

|

D.When

cutting or drilling into a wall or ceiling, be

careful not to damage electrical wiring and other

hidden utilities. |

|

|

|

|

|

|

|

|

|

WARNING WARNING |

|

|

|

Precaution

should be taken in explosive atmospheres. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

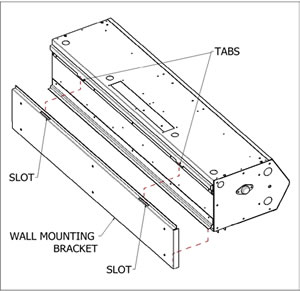

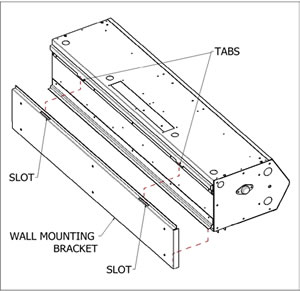

Note: If the holes provided on the bottom of the unit

and the bottom of the wall mounting plate do not align,

remove the unit and re-install. The holes on the bottom

channel of the wall mounted plate must be on the

bottom. |

|

WARNING WARNING |

|

|

When

servicing the product, motor may be hot enough to

cause pain or injury. Allow motor to cool before servicing. |

|

|

|

|

|

| RECEIVING

AND INSPECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

Upon

receiving the product, check to make sure all items

are accounted for by referencing the Bill of Lading to

ensure all items were received. Inspect each carton for

shipping damage before accepting delivery. Notify the

freight carrier if any damage is noticed. The carrier will

make notification on the delivery receipt acknowledging

any damage to the product. All damage should be noted

on all copies of the Bill of Lading which is countersigned

by the delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival and a report

given to the Traffic Department. If damaged upon arrival,

file a claim immediately with the carrier. Any physical

damage to the unit after acceptance is not our

responsibility. |

|

|

|

|

|

|

|

| UNPACKING |

|

|

|

|

|

|

|

|

|

|

Verify

that all parts, components and accessories, and the

correct quantities of each have been received. If any items

are missing, report shortages to Mars Air Systems directly

to arrange for obtaining the missing items. Again, verify

quantities received against those on the Bill of Lading only,

as multiple shipments may be involved. |

|

FIG.

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| INSTALLATION |

|

|

|

|

Typical

Mounting – Wall or Ceiling Mounted

Horizontally Above the Door Opening |

|

|

|

|

1.

Remove the air intake grille(s) and/or air intake filter(s)

from the product and set aside. Gently remove all

packaging materials, hardware and all other accessories

from interior of unit prior to operating. Severe unit

damage will occur if these items are not removed prior

to operation. |

|

|

|

|

2.

Lay unit on its top with directional vanes pointing up

and remove the Tek Screws from the wall mounting

plate, just behind the discharge nozzle, and remove

the mounting plate from the unit. (FIG. 1) Measure

the mounting plate and center it over the opening.

The air curtain shall be equal to or greater than

the

width of the opening. |

|

|

|

|

|

|

|

FIG.

2 |

|

|

|

|

|

|

|

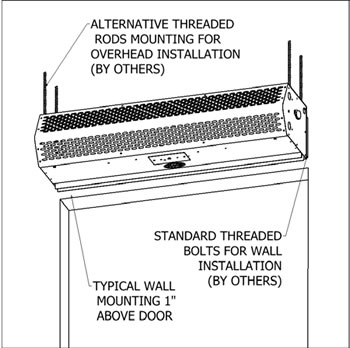

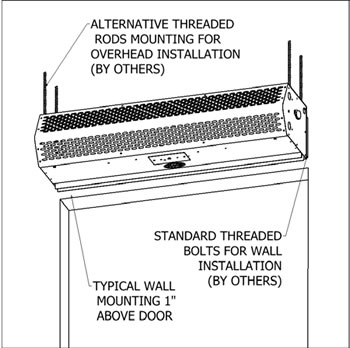

5.

Mount the product such that the discharge is 1” above

the opening and all obstacles. (FIG. 3) |

|

|

|

Note:

If the product is installed higher than the

recommended 1” above the opening, then it must be

moved 3/8” away from the wall for every 1” that it is

moved up. Any void between the wall and the product

must be sealed, by others, to optimize performance. |

|

3.

Install the mounting plate(s) above the opening.

Multiple pre-punched 7/16” mounting holes are

provided for your convenience. These holes must

be utilized to secure the product to the wall. All

hardware is field provided by others. |

|

|

|

|

|

|

|

|

|

6.

Use four (4) threaded rods for overhead installation

or four (4) threaded bolts for wall installation. All

hardware is field provided by others. (FIG. 3) |

|

4.

Align the tabs on the rear of the unit with the slots

provided on the wall mounting plate (FIG. 2). The

bottom flange on the unit must also drop in the

bottom channel of the wall mounting plate. Replace

the Tek Screws to secure the unit in place. |

|

|

|

|

|

|

|

|

|

|

NOTE |

|

|

|

For

accessory installation, reference Accessory Installation

Supplement.

For heated products, reference Heated Products

Supplement. |

|

|

|

|

START-UP |

|

This

product has been assembled and tested at the factory

prior to shipping. The following procedures should be

performed to assure its performance. Before continuing

with the start-up, it is important to recognize the safety

controls furnished with the unit. |

|

|

|

|

WARNING WARNING |

|

Prevent

hazard of electrical shock. More than one

disconnect switch may be required to de-energize this

product. |

|

|

|

|

WARNING WARNING |

|

|

FIG.

3 |

|

|

|

|

The

following items must all be completed by a qualified

installer and checked off when completed |

|

|

|

|

|

7.

If applicable, optional Adjustable Mounting Brackets,

Side Extension Plates and Extended Wall Mounted

Brackets are also available for installations over a

Vertical Lift or Drum Roll-up type door. (Reference

Accessory Installation Supplement)

8. If applicable, for tandem installation or products

mounted side by side, allow no more than 6” between

the two products. For overhead installation using

threaded rods, the products may require a beam, by

others, to span the full distance of the mounting length.

(Reference Accessory Installation Supplement)

9. All wires must be connected internal of the unit and

some knockouts are provided. However, it may be

necessary to create your own knockout, as required.

10. The unit must be wired per NEC and local codes. |

|

A.

Re-check that the product has been installed properly

and is level and secure.

B. Check all terminal screws are tight and field wiring is

connected in accordance to National Electrical Code

and wired per the enclosed wiring diagram. For electric

heated models, ensure that the coils are secured and

not

touching each other on any metal surface.

C. Verify proper voltage prior to powering the product.

(See product label for reference).

D. Check all field wired components “if supplied” are

wired correctly.

E. Check that the inlet air supply and the discharge air

supply are free of obstructions.

F. Check that all air filter(s) and/or air intake grille(s) are

in place and installed properly, as originally shipped.

G. Verify voltage to the product once more and turn

power on.

H. Regardless of whether the product is mounted on the

inside or outside of the door opening, set the air

directional vanes in the discharge nozzle slightly

outward to approximately 10-15° towards the outside,

or the wind load. (FIG. 5). |

|

|

|

|

|

| Electrical

Field Wiring |

|

The

unit and any optional accessories must be wired with

the proper voltage to the junction box per the wiring

diagram. (FIG. 4, unheated products only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

FIG. 5 |

|

|

|

|

I.

For products with control panels, turn the HOA

(Hand-On-Auto) selector switch to “On” position and

open the door to energize the product. For products

without a control panel or an On/Off switch, open the

door to energize the product. |

|

|

FIG.

4 |

|

|

|

|

|

| MAINTENANCE |

J.

If heated products are installed, reference Heated

Products Supplement.

K. For three phase units, verify direction of rotation of

blower wheels (note direction arrows on the blower

wheel housing). Correct if needed by changing polarity

of three phase power.

L. VERY IMPORTANT Using a clamp meter, measure

the amperage to each motor and ensure that they do

not exceed the amperage listed on the product label. |

|

|

WARNING WARNING |

|

To

reduce the risk of fire, electrical shock or injury to

persons, observe the following:

A. Maintenance is to be performed only by qualified

personnel who are familiar with local codes and

regulations and are experienced with this type of

product.

B. Before servicing or cleaning the product switch power

off at service panel and lock service panel to prevent

power from being switched “ON” accidentally. |

|

|

M.

If applicable, adjust the air intake grille(s) such that

the output air stream reaches the floor.

For tem-

perature control and environmental separation

applications, the air stream should reach

the floor

with sufficient strength to create an air

seal around

the door opening without creating turbulent mixing

of the inside and outside air. For flying

insect control

applications, the air stream should reach

the floor with

maximum strength. If after proper installation

and

adjustment, the product appears to be producing

too little or too much air for the application,

contact

the manufacturer. |

|

|

Routine

maintenance is required to keep this product

operating at its peak performance and efficiency. Over

time, the housing, air intake grille, air intake filter, blower

wheels and motor(s) will accumulate a build up of dust,

debris and other residue. It is imperative to keep these

components clean. Failure to do so will not only lower

operational efficiency and performance, but also reduce

the useful life of the product. The time between cleanings

depends on the application, location and daily hours of use.

On average, under normal use conditions, the product

should require a thorough cleaning once every

six (6) months. |

|

|

|

|

|

|

| To

clean the product, perform the following: |

4.

Thoroughly clean the air intake grille(s)/filter(s).

5. Thoroughly wipe down the motor, blower wheels

and blower wheel housings. Be careful not to spray

the motor with a water hose.

6. The motor(s) require no additional lubrication. They

are permanently lubricated and feature double sealed

ball bearings.

7. To re-install the product, reverse the procedures above.

8. Reconnect the power source to the product.

9. If you have any questions regarding the maintenance

of the product, contact the manufacturer. |

1.

Verify the product has been disconnected from the

power source.

2. Use a damp cloth and either a warm mild soapy water

solution or bio-degradable degreaser, to wipe down the

exterior components of the housing.

3. To access the interior of the product, remove the air

intake grille(s) and/or air intake filter(s). This is

accomplished by removing the screws on the face of

the air intake grille(s)/filter(s). |

|

|

|

Commercial Air Curtains,

Air Curtain, Air Curtain Door, Air Curtain Heater, Air Curtains, Air Doors,

Door Air Curtains, Heat

Curtains, Mars Air Curtain, Mars Air Door, Warm Air Curtains, and Insect

Barrier from your source for material handling

equipment. |

Back

to Product Category |

|

|