|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

KEE

SELF-CLOSING SAFETY GATES

|

| Choose

high quality, fully compliant and extensively tested safety |

|

|

|

|

| Access

the safest gates around |

|

|

|

|

A

fully adjustable range of self closing safety gates for use in rooftop or

industrial environments. Self closing safety

gates are ideal for protecting any openings, ladder/stair access points,

roof hatches, walkways, access to industrial

machinery and other restricted areas, where regular access for maintenance

and inspection is needed. |

|

|

|

|

|

|

|

|

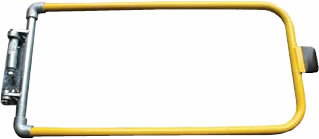

|

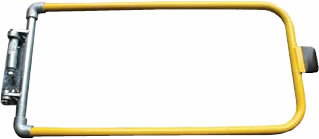

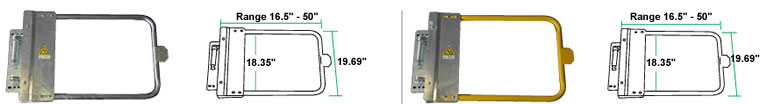

Powder

Coated Safety Yellow:

SGNA500PC |

|

Galvanized:

SGNA500GV |

|

|

|

| Our

gates are spring loaded so will automatically close behind the user. |

|

| Why

do you need Kee Self-Closing Gates? |

|

Different

Options

Kee Gate® Access is available with three different options. These are

the single-width gate, double-width gate

and full height gates. This means you can find the gate that best suits

your site – from small areas to larger areas

to ladders. You can also easily cut the gates to size on site. |

|

Self

Closing

Our gates are spring-loaded so will automatically close behind the user.

Spring-loaded safety gates are

considered the preferred solution to chains, bars or sliding tubes when

protecting these areas as they

automatically close behind a person, overcoming the problem of human error. |

|

Extensively

Tested

The safety gates passed salt spray testing to ASTM B117-11-55 Neutral solution

over 200 hours to

assess the performance of coating to resist corrosion. Our gates were also

abuse tested and the mechanism

tested to over 50,000 open/close cycles. |

|

|

|

|

|

|

Key features

of

Kee Self-Closing

Safety Gates |

|

|

|

Can

fit different surfaces (round or square)

and can be used for external and internal

applications. They are quick and easy to

install which saves time and money. |

•

Spring Loaded

• Finish Options

• Size Options

• Simple

• Adjustable

• Versatile |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

Model

No. |

Description |

Price |

SGNA500GV |

Universal

self-closing safety gate; adjustable 18"-44", Galvanized |

|

SGNA500PC |

Universal

self-closing safety gate; adjustable 18"-44", Safety Yellow

PC |

|

|

|

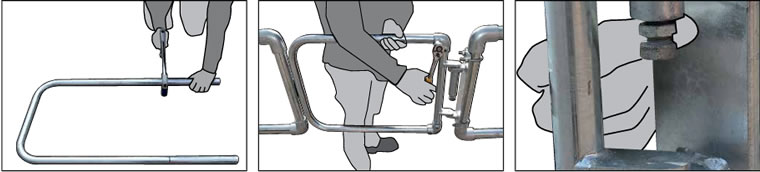

Safety

Gate Assembly Instructions |

|

|

|

|

|

|

|

|

|

|

|

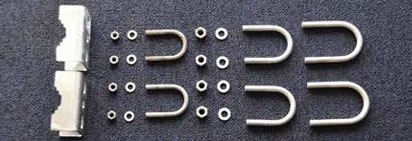

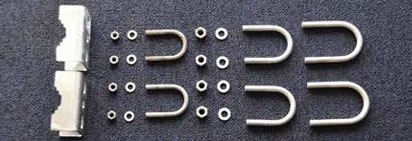

SAFETY GATE

FIXING PACK 1 - SGNAFXPK1

Supplied for the USA market to fit posts 1.0”, 1.25” and 1.5”

diameter. Fixing pack contains 3No U Bolts for each size

complete with 0.3125” and 0.375” nuts and washers.

Material : Galvanised steel to ASTM A53.

Net weight : 1.44kg (3lb 3oz). |

|

|

|

|

|

|

|

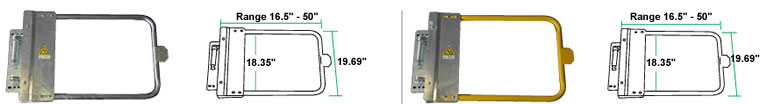

SGNA500GV

GATE - GALVANISED

Spring Loaded, self-closing safety gate. Each model can be

adjusted on site without need for cutting or welding.

Complete with fixing pack.

Material : Galvanised steel to ASTM A53. |

SGNA500PC

GATE - POWDER COATED

Spring Loaded, self-closing safety gate. Each model

can be adjusted on site without need for cutting or

welding. Complete with fixing pack. Powder Coated

USA - AAMA 2603-2605.

Material : Galvanised steel to ASTM A53. |

|

|

|

|

Mounting

and tensioning gate spring |

|

|

|

|

|

|

| TOOLS

REQUIRED |

|

|

You

will need the following in order

to install the Kee Gate: |

|

|

•

Marker Pen

• Tape Measure

• 1No 24mm Ring Spanners

• 1No 13mm socket

• No 17mm socket

• 1No 24mm socket

• ¼” Hex Key Socket

• Torque Wrench 10- 60 Nm approx

• Hacksaw or Similar

• Small Magnetic Level |

|

|

|

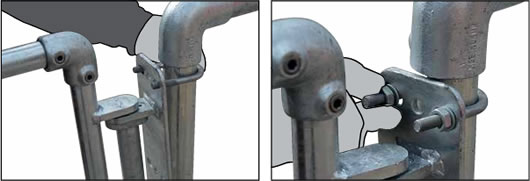

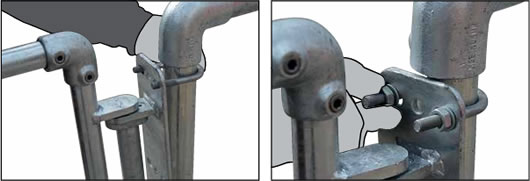

A.

Align the fixing plate on internal face

of the opening, so that the rails of the Safety

Gate match up with the top of the Guardrail

System. Select the correct U Bolt & pass

around the support leg/structure and feed

through the top holes of the fixing plate. |

|

B. Using a M8 or M10 flat washer and nut

connect the U bolt to the Support Leg/

Structure and tighten. |

|

|

|

|

Mounting

Gate to Upright

Establish that the gate will close in

direction of hazard!! Failure to do

so could result in Death or serious

injury. |

|

|

|

|

|

|

|

|

|

|

|

|

C. Pass U-Bolt around the support

leg/structure and feed through the bottom

holes of the fixing plate. |

|

D. Using a M8 or M10 flat washer and nut

connect the U bolt to the Support eg/

Structure and tighten. |

|

E. Torque all nuts/U Bolts to 25Nm using

the 13mm or 17mm socket and torque

wrench. |

|

|

|

|

|

|

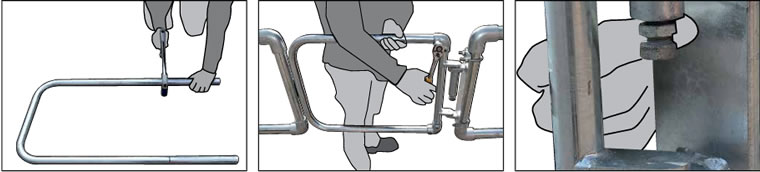

F. To cut the gate to the correct size simply

place a straight edge/magnetic level as

shown and measure the distance to the

point where the outside edge of the

vertical tube meets the supporting

structure as shown. (DO NOT CUT

AT THIS MARK!) |

|

G. Disconnect the tubular gate from the

hinge assembly by loosening the top &

bottom cast clamp grub screw using a hex

head socket as shown. |

|

H. Measure the distance recorded in

point (f) above and mark the gate top

and bottom tubes as shown. |

|

|

|

|

|

|

|

|

|

|

|

|

|

I. Using a hacksaw or similar carefully cut

through the top and bottom tubes as

shown. For galvanised assemblies, spray

with Galvafoid or similar to prevent

corrosion. |

|

J. Carefully re-position the gate top and

bottom tubes into the cast fittings. Ensure

the striking plate is on the correct side of

the Support Leg/Structure. Use a spirit

level, to ensure the gate is level. Tighten

the cast fittings grub screws using a hex

head socket. Using the torque wrench

ensure the castings are torqued to 39Nm. |

|

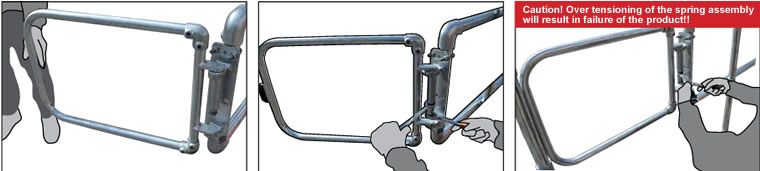

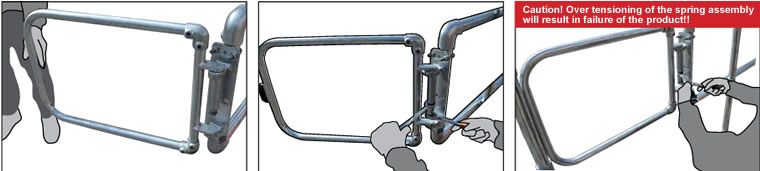

K. To tension the hinge loosen the

locking nut as shown. |

|

|

|

|

|

|

|

|

|

|

|

|

L. Manually open the gate at 45 degrees

from its closed position. |

|

M. Using the 24mm socket & ring span-

ner start to tighten the bolt until the gate

completely closes. (Note:- You may have

to hold the socket whilst using the

ratchet). |

N. Once the gate is completely closed

tighten the locking nut to hold the tension.

Caution:- Continue to hold the ratchet

firmly and do not release until the lock nut

is tightened. Now remove the socket and

spanner from the hinge. Repeat as neces-

sary, to ensure that the gate closes suf-

ficiently, once opened and released. |

|

|

|

|

|

|

|

|

|

Note:-

Installing Kee Gate

When installing Kee Gate on a pitched

roof it is essential that the gate is mounted

vertically level to the horizontal. This can

be accommodated by using standard

90 degree Elbows (15-8)

(4No required per gate). |

|

|

|

The

elbows permit adjustment allowing

the Kee Gate to be orientated to the correct

angle. If the gate is not set at the correct

angle the hinge cannot be tensioned

correctly and the gate may not close as

required. |

|

|

|

Kee Self-Closing Safety Gates,

Mezzanine Safety Gates, Safety Gates, Self-Closing Safety Gates, Platform

Safety Gates, Safety

Gate, and Kee Gate Access from your complete source for material handling

equipment. |

Back

to Product Category |

|

|