|

HOT

DIPPED GALVANIZING

|

|

|

|

|

|

|

|

|

|

NEW!

- Hot dipped galvanized finish |

|

|

|

|

|

|

|

The

steel products displayed on this thumbnail page are now available

with a corrosion resistant finish applied to the steel after

fabrication.

Contact us for pricing! |

|

|

|

|

|

|

|

Hot

Dipped Galvanizing Corrosion Protection with Zinc

|

|

|

|

|

|

|

|

Steel

used to construct buildings, equipment, ornamental iron, bolts,

nuts and other small parts requires corrosion protection. The

proven

effectiveness of zinc in controlling corrosion makes it an ideal

choice

for protecting structural steel. Hot dipped galvanizing is generally

the

most effective method of applying zinc to steel. |

|

|

|

|

|

|

|

Why

Galvanizing Works |

|

|

|

|

|

|

|

The

excellent corrosion resistance of hot dipped galvanized steel

is due

to the two fold nature of the coating. The zinc coating provides

barrier

and cathodic protection to the underlying steel surface. |

|

|

|

|

|

|

|

|

|

|

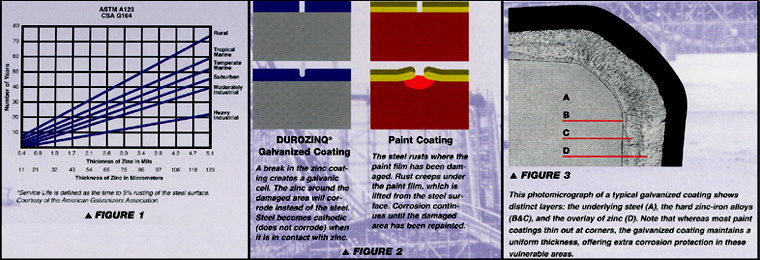

During

the Galvanizing process, steel reacts with molten zinc to form

a series of zinc-iron alloy layers which, together with the

outer zinc

layer, are metallurgically bonded to the steel surface. The

resulting

barrier coating has a very low corrosion rate (Figure 1) and,

because

of the hard alloy layers, is highly resistant to mechanical

damage.

Galvanized steel is much less susceptible to coating damage

from

handling than is painted steel. |

|

|

|

|

|

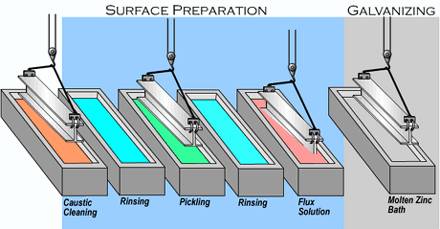

As

the name implies, hot dipped galvanizing requires complete immersion

of the work piece in molten zinc. This process ensures a uniform

coating

on all surfaces, even on those areas not normally accessible

to mechan-

ical applicators. |

|

|

|

|

|

|

|

|

|

Zinc

corrodes preferentially to steel and provides cathodic protection

to

areas of bare steel (up to 1/4 inch wide) accidentally exposed

in service.

The sacrificial nature of zinc prevents the steel from corroding

adjacent

to the galvanized coating, thus preventing undercutting and

blistering of

the protective film. In comparison, exposed steel on painted

surfaces

will corrode immediately. The resulting rust occupies several

times the

volume of steel from which it was formed, causing the lifting

and

subsequent flaking of the adjacent paint film (Figure 2). |

|

|

|

CONTACT

US FOR PRICING!

|

|

|

|

|

|

|

|