|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back to Product Category

COMMERCIAL

Low Profile 8 Air Curtains |

(AMBIENT,

UNHEATED) |

|

|

|

|

|

|

Designed

to meet the functional needs of the

application and to integrate into the space. |

|

|

|

|

IDEAL APPLICATIONS: |

|

|

Service / Employee

Doors

Main Entrances

Concessions / Drive-Thrus

Shopping Carts

Walk-in Coolers |

|

|

|

|

|

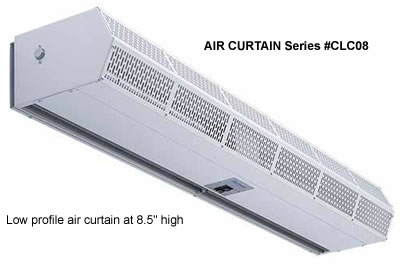

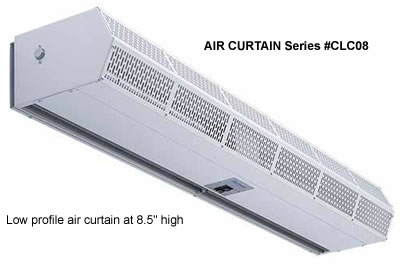

Low

profile air curtain with white or black

powder coated cabinet. |

|

|

|

|

Custom

Colors & Stainless Steel Available

Call us for a quote. |

|

|

|

|

| For

mounting heights up to 8' (environmental separation) and 7'

(insect control) |

|

|

|

|

| Standard

Construction |

|

|

Installation

& Mounting |

•

8 ½” high x 13 ½” deep

• 1/5 hp two speed motor(s)

• Factory installed fan speed switch

• White or black powder coated exterior

• Wall & Top Mounting |

|

|

Simple to install,

operate & maintain |

|

|

(Click

here for Installation & Maintenance Instructions) |

|

|

|

|

|

•

Single lengths up to 10’

• No Assembly Required

• Wall plate included

• 1/4” threaded inserts for top mounting

• Bottom access panel for easy access to internal

components |

|

|

|

•

Parts Warranty:

Ambient - Five years |

|

|

|

|

|

| Control

Packages: |

|

|

| •

Deluxe |

|

|

|

|

|

|

|

Building

Automation & Door Controller versions available. |

|

|

|

Air

curtains provide environmental separation at

openings by reducing the infiltration of unconditioned

air, fumes, dust, and humidity. At exterior openings,

they can resist winds up to 8 MPH (13 KPH) and are

generally mounted inside the building. During cold

seasons warm air that has risen towards ceiling is re-

circulated; they can also be used at interior openings

such as doors to coolers or clean rooms. |

|

Optimum

protection is provided when units are

mounted flush to the wall and as close to top of

door opening as possible. To ensure peak per-

formance keep air stream free of obstructions.

Air curtains may not be fully effective where negative

air pressure exists on one side of door. |

|

|

|

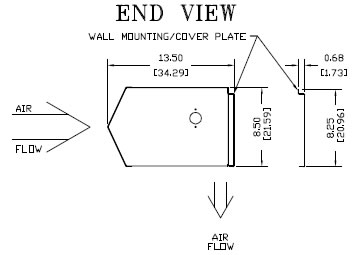

Series

CLC08 model air curtains have 1/5 HP motors.

They can be wall mounted or suspended from the

ceiling. |

|

|

|

| COMMERCIAL

LOW PROFILE 8 Ambient (Unheated) Air Curtain Data Sheet |

MODEL |

Nozzle

Width (in) |

Max

Vel.

at Nozzle

(fpm) |

Avg.

Outlet

Vel. (fpm) |

Air

Volume

(cfm) |

Outlet

Vel.

Uniformity |

Power

Rating

(kW)

| Motor(s)

@ hp |

Net

Wt.

(lbs) |

CLC08-1042A |

40.62 |

3,388 |

1,755 |

1,176 |

93% |

0.32 |

1

@ 1/5 |

45 |

CLC08-1048A |

46.62 |

3,226 |

1,742 |

1,340 |

94% |

0.32 |

1

@ 1/5 |

48 |

CLC08-1060A |

58.13 |

2,940 |

1,702 |

1,632 |

95% |

0.32 |

1

@ 1/5 |

56 |

CLC08-1072A |

71.37 |

2,870 |

1,707 |

2,010 |

95% |

0.32 |

1

@ 1/5 |

64 |

CLC08-2084A |

83.5 |

3,388 |

1,707 |

2,351 |

93% |

0.64 |

2

@ 1/5 |

90 |

CLC08-2096A |

95.5 |

3,226 |

1,701 |

2,679 |

94% |

0.64 |

2

@ 1/5 |

98 |

CLC08-2108A |

107 |

3,226 |

1,684 |

2,971 |

94% |

0.64 |

2

@ 1/5 |

105 |

CLC08-2120A |

118.5 |

2,940 |

1,670 |

3,263 |

95% |

0.64 |

2

@ 1/5 |

113 |

|

|

|

NOTE:

1. Operation at 50 Hz will generate approximately a 17% reduction in performance

2. Consult us for vertically mounted units. |

|

|

COMMERCIAL

LOW PROFILE 8 Ambient (Unheated) Air Curtain

Electrical Performance Sheet |

MODEL |

#

Ckts |

120/1/60

(voltage code Z)

MOTOR AMP DRAW = 3.4 ea. |

208/1/60

(voltage code B)

MOTOR AMP DRAW = 1.7 ea. |

240/1/60

(voltage code B)

MOTOR AMP DRAW = 1.7 ea. |

Amps

per

Circuit |

Breaker

Rating per

Circuit |

Amps

per

Circuit |

Breaker

Rating per

Circuit |

Amps

per

Circuit |

Breaker

Rating per

Circuit |

CLC08-1042A |

1 |

3.4 |

15 |

1.7 |

15 |

1.7 |

15 |

CLC08-1048A |

CLC08-1060A |

CLC08-1072A |

CLC08-2084A |

1 |

6.8 |

15 |

3.4 |

15 |

3.4 |

15 |

CLC08-2096A |

CLC08-2108A |

CLC08-2120A |

|

|

|

480/3/60

(voltage code Z) |

MOTOR

AMP DRAW = 0.9 each |

MODEL |

#

Ckts |

Amps

per Circuit |

Breaker

Rating per Circuit |

CLC08-1036A |

1 |

0.9 |

15 |

CLC08-1042A |

CLC08-1048A |

CLC08-1060A |

CLC08-1072A |

CLC08-2084A |

1 |

1.8 |

15 |

CLC08-2096A |

CLC08-2108A |

CLC08-2120A |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click the Model No. of the item you wish

to purchase. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

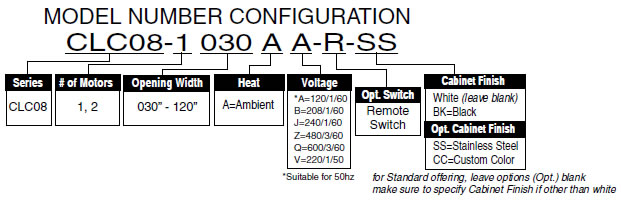

Specify

voltage and color.

White is standard. |

|

|

|

|

PRICING

FOR COMMERCIAL LOW PROFILE (UNHEATED) AIR CURTAIN |

Model

No.

120/208/240/1/60 |

Price |

Model

No.

480/3/60

| Price |

|

$1,179 |

|

$1,798 |

|

$1,200 |

|

$1,819 |

|

$1,279 |

|

$1,833 |

|

$1,359 |

|

$1,931 |

|

$1,492 |

|

$2,095 |

|

$2,519 |

|

$3,009 |

|

$2,549 |

|

$3,101 |

|

$2,665 |

|

$3,225 |

|

$2,669 |

|

$3,260 |

|

Model

No. |

Description |

Price |

|

| Deluxe

Low Voltage Control (includes time delay relay,

24 volt control transfomer, and magentic reed door switch) |

$398 |

|

|

CLC08

AMBIENT SYSTEM |

|

|

|

|

|

|

NOTE: |

|

|

|

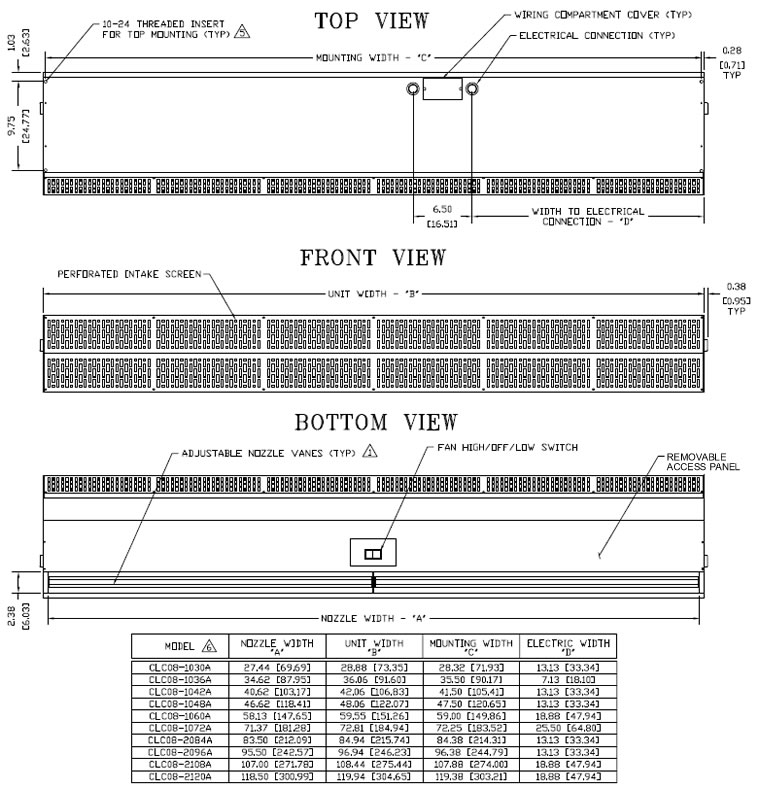

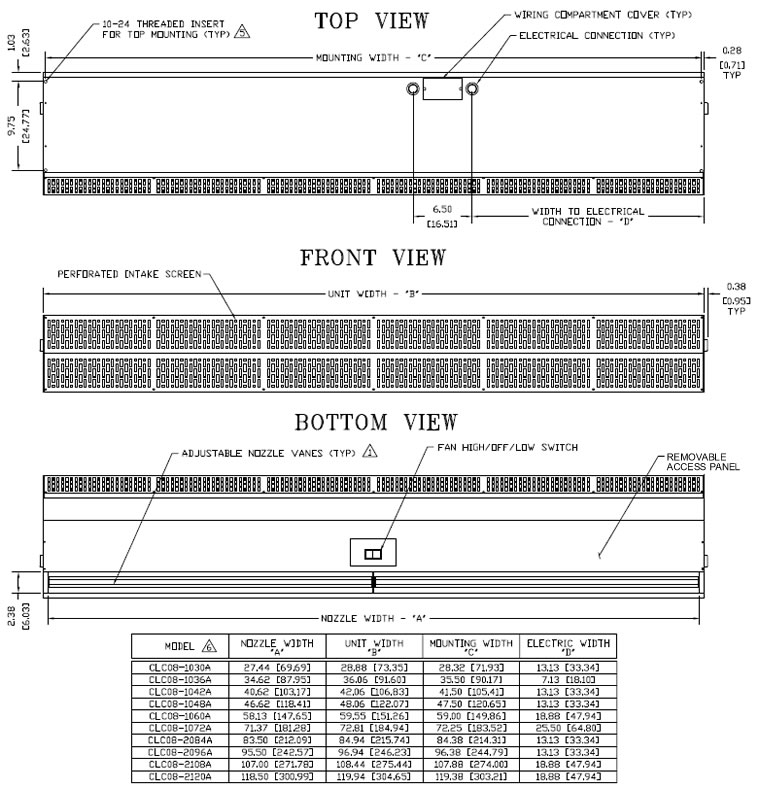

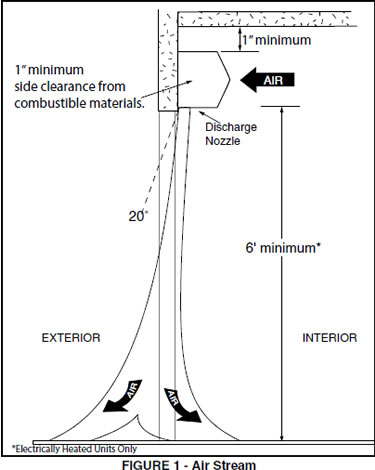

1. Air curtain

must be installed so air stream is not

obstructed when deflected 20° to either side of C. |

|

2. Electrical

connections to be flexible. |

|

3. Field verify

dimensions. |

|

4. Anchors to

supporting structure by others. |

|

5. Adequacy of

supporting structure is to be verified

by a professional structural engineer. |

|

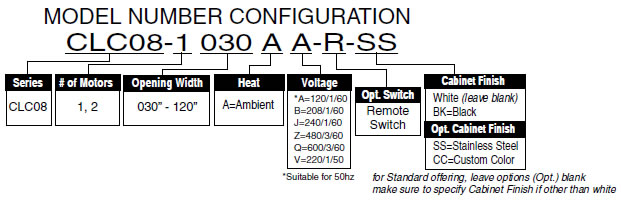

6. Letter "A"

in model number designates ambient unit. |

|

7. Dimensions

in inches [centimeters]. |

|

|

|

top

of page |

|

INSTALLATION

& MAINTENANCE INSTRUCTIONS |

|

|

|

|

|

|

SANITATION

CERTIFIED

Low Profile 7

AIR CURTAIN SERIES SLC07 |

|

|

|

|

COMMERCIAL

Low Profile 8

AIR CURTAIN SERIES CLC08 |

|

|

|

|

TABLE

OF CONTENTS |

|

I.

UNCRATING

II. MOUNTING INSTRUCTIONS

III. WALL MOUNTING

IV. SUSPENDED MOUNTING

V. ELECTRICAL CONNECTIONS

VI. MECHANICAL CONNECTIONS

VII. AIRFLOW ADJUSTMENTS

VIII. MAINTENANCE AND CLEANING

IX. SERVICE |

|

|

|

WARNING:

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING: |

A.

Read all instructions before installing or using this air curtain.

B. Use this unit only in the manner intended by the manufacturer and described

in this manual. Any other use not recommended

by the manufacturer may cause fire, electric shock,

or injury to persons. If you have any questions, contact the manufacturer.

C. Before servicing or cleaning unit, switch power off at service panel

and lock the service disconnecting means to prevent power

from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

D. Installation work and electrical wiring must be done by qualified person(s)

in accordance with all applicable national and local

codes having jurisdiction, including fire-rated

construction. See below, ELECTRICAL CONNECTIONS (NEC Code ANSI/NFPA

No. 70).

E. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

F. To reduce the risk of fire, do not store or use gasoline or other flammable

vapors and liquids in the vicinity of the air curtain.

G. This air curtain is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces. Keep combustible materials, such

as furniture, pillows, bedding, papers, clothes,

etc. and curtains at least 1 inch from the top, back, front, sides and at

least

6 feet from the discharge of the air curtain.

H. Extreme caution is necessary when any air curtain is used by or near

children or invalids, and whenever the heater is left

operating unattended.

I. Do not operate any air curtain after it malfunctions. Disconnect power

at the service panel and have the air curtain inspected

by a reputable electrician before reusing.

J. To disconnect the air curtain, turn controls to “off”, and

turn off power to the air curtain circuit at main disconnect panel.

K. Do not insert or allow foreign objects to enter any ventilation or discharge

opening as this may cause an electric shock or fire,

or damage the air curtain.

L. To prevent a possible fire, do not block the air intake or discharge

of the air curtain in any manner.

M. The air curtain has hot and arcing or sparking parts inside. Do not use

it in areas where gasoline, paint, or flammable vapors

or liquids are used or stored.

N. This heater may include an audible or visual alarm to warn that parts

of the heater are getting excessively hot. If the alarm

sounds (or illuminates), immediately turn

the heater off and inspect for any objects on or adjacent to the heater

that may have

blocked the airflow or otherwise caused high

temperatures to have occurred.

DO NOT OPERATE THE HEATER WITH THE ALARM SOUNDING (OR ILLUMINATING). |

|

|

| I.

UNCRATING THE AIR CURTAIN UNIT |

|

Carefully

examine the carton(s) for damage before

opening. If the carton is damaged, immediately notify

the shipping company. If the unit(s) were shipped on

wooden skids, remove protective wood and banding

straps securing the carton(s) to the skid. Open the

carton(s) and remove all protective packaging. Re-

move the plastic cover housing by lifting vertically.

Remove and discard four (4) nuts and washers

holding the motor/ blower section to the bottom

of the carton. Remove motor/blower section from

the carton. |

MODEL |

Net

Weight (lbs) |

SLC07

Ambient |

CLC08

Ambient |

CLC08

Electric |

CLC08

St/Hw |

SLC07-1036,

CLC08-1036 |

35 |

41 |

48 |

67 |

SLC07-1042,

CLC08-1042 |

38 |

45 |

53 |

74 |

SLC07-1048,

CLC08-1048 |

42 |

48 |

58 |

80 |

SLC07-1060,

CLC08-1060 |

49 |

56 |

67 |

94 |

SLC07-1072,

CLC08-1072 |

56 |

64 |

77 |

107 |

SLC07-2084,

CLC08-2084 |

76 |

90 |

105 |

138 |

SLC07-2096,

CLC08-2096 |

84 |

98 |

115 |

152 |

SLC07-2108,

CLC08-2108 |

91 |

105 |

123 |

164 |

SLC07-2120,

CLC08-2120 |

98 |

113 |

137 |

177 |

|

|

CAUTION:

ONLY LIFT THE UNIT BY

GRASPING INLET RINGS ON THE BLOWER

HOUSING WITHOUT TOUCHING BLOWER

WHEELS. |

|

|

|

Immediately

verify that the electrical rating nameplate

located on the cover matches electrical power supply

available. Retain the shipping carton(s) until the unit(s)

are installed and properly operating. ACCESSORIES:

If the unit(s) were ordered with optional electrical

accessories (door switch, control panel, etc.), the

accessories may be found in the carton containing the

unit or in a separate carton(s) accompanying the unit(s).

Check all of the cartons/skids for accessories before

discarding. |

|

TABLE

1 - Weight Chart |

|

|

|

|

|

|

|

|

| II.

MOUNTING INSTRUCTIONS (General) |

|

|

Before

mounting the unit, check the supporting structure

to verify that it has sufficient load-carrying capacity to

support the weight of the unit(s). The mounting hardware

(supplied by others) should be capable of supporting a

minimum of three (3) times the weight of the unit.

See TABLE 1. |

The

Certified Low Profile 7/Commercial Low Profile 8

air curtain is designed to be an ef.fective barrier against

cold drafts in the winter and hot air in the summer, flying

insects and airborne contaminants. To achieve optimum

protection, the unit should be mounted on the inside of

the building, flush to the wall and as close to the top of

the door opening as possible. To ensure peak per-

formance, keep air stream free of obstructions. |

|

|

|

|

|

|

|

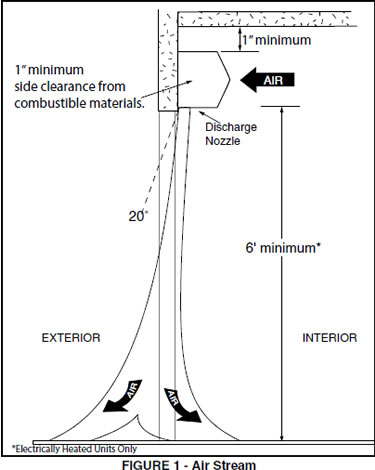

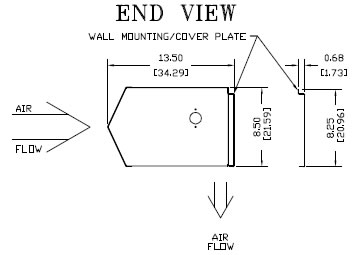

A.

When determining the mounting location for the |

|

|

|

unit(s),

make sure that nothing interferes with the

curtain of air developed when the discharge vanes

are directed from 0° to 20° toward the door

opening. If the air stream strikes any obstruction

(the top edge of the doorway, a door opening

device, etc.), the ef.fectiveness of the unit will be

greatly reduced. See FIGURE 1. |

|

|

|

|

The

air curtain will not perform properly if negative air

pressure exists in the building. Under these conditions,

a means for make-up air to the building must be provided

so that the air pressure on both sides of the opening is

in balance. |

|

|

|

|

|

|

|

|

|

|

|

|

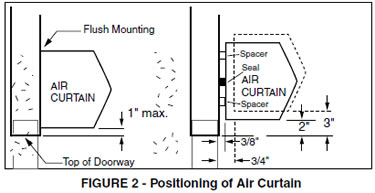

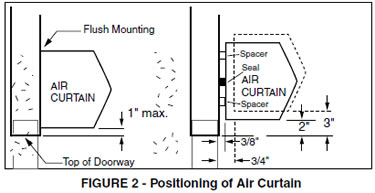

B.

For optimum performance, the bottom of the unit |

|

|

|

(discharge nozzle)

should be no more than 1” above

the top of the door opening with the unit mounted

flush to the wall. If the unit must be mounted higher,

it must be spaced out from the wall 3/8” for every

inch the unit is above the door opening. Any void

between the air curtain and the wall should be

sealed along the full length of the unit.

See FIGURE 2. |

|

C.

Proceed to: Section III-WALL MOUNTING |

|

|

|

or Section

IV-SUSPENDED MOUNTING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| III.

WALL MOUNTING |

|

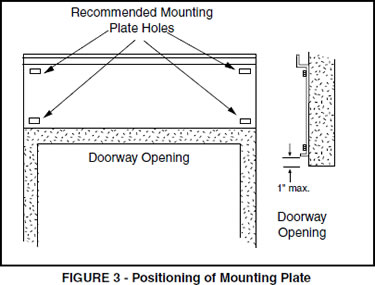

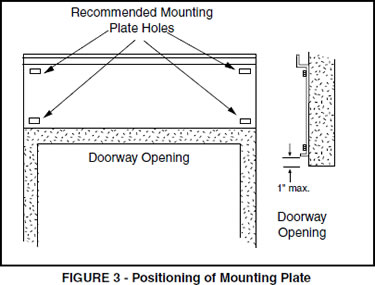

| A.

Determine the location on the wall above the opening |

|

|

where

the air curtain will be mounted. This location

should center the unit over the opening and provide

suitable mounting support. It is recommended to use

at least four locations that correspond to the outer

corners of the wall mounting plate.

See FIGURE 3. |

|

|

|

|

|

|

|

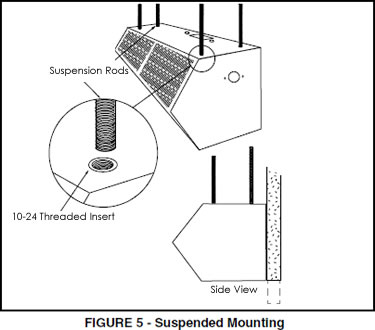

IV.

SUSPENDED MOUNTING

(Ceiling Suspension) |

|

|

|

B.

Prepare the wall as necessary for the wall mounting

plate anchors (by others). |

|

|

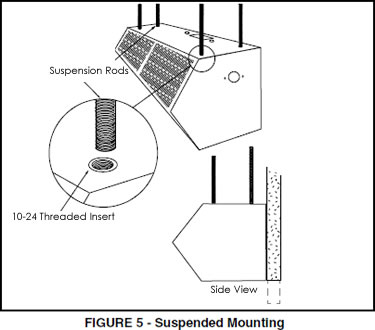

A.

When the unit is top mounted, the wall mounting |

|

|

plate

is designed to store on the back of unit for

future use. |

|

|

|

|

C.

Drill holes in the wall mounting plate to correspond

to the locations on the wall. |

|

|

|

|

|

|

B.

Four (4) factory installed #10-24 threaded inserts |

|

|

|

|

|

|

|

are

located on the top of the unit for top suspension

mounting. See FIGURE 5. |

D.

Anchor the wall mounting plate over the door

opening with the mounting tabs pointing upwards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

C.

Determine the exact mounting location of the air

curtain. |

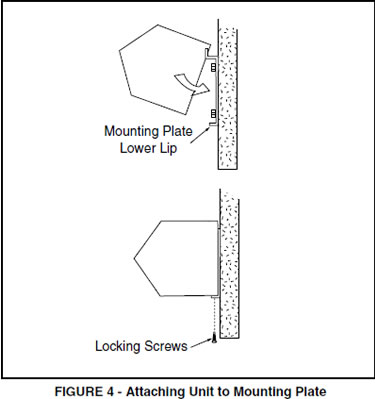

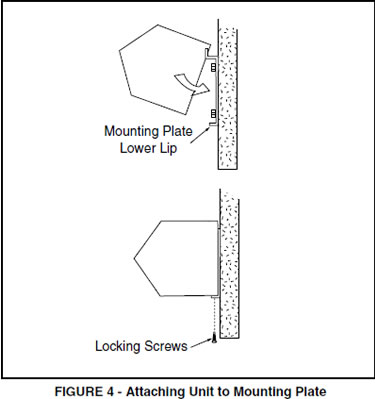

| E.

Raise the unit over the door (air nozzle facing |

|

|

down)

and onto the mounting plate. Tilt the unit

upward, matching the holes in the frame with the

tabs on the mounting plate.

See FIGURE 4. |

|

|

|

|

|

|

|

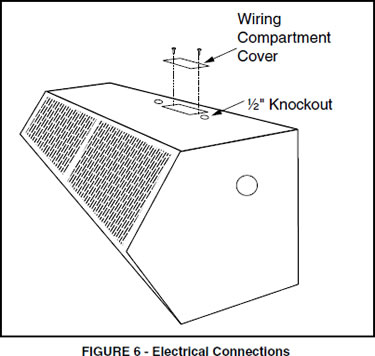

D.

The top of the unit is provided with an electrical |

|

|

|

knockout

for power connection. Remove the wiring

tray compartment cover. Remove the knockout and

attach necessary electrical hardware. Save the wiring

diagram found inside of wiring tray. |

|

|

|

|

| F.

Lower the unit into place allowing it to rest on the |

|

|

|

mounting

plate. The unit flange should rest above the

mounting plate flange. |

|

|

|

|

|

|

|

|

E.

Attach #10-24 threaded rods, or other suitable

hardware to the top mounted threaded inserts |

|

|

|

G.

After the unit is securely seated to the mounting plate,

install the locking screws along the bottom flange.

See FIGURE 4. |

|

|

|

|

|

F.

Proceed to Section V-ELECTRICAL

CONNECTIONS |

|

|

|

|

|

|

|

|

H.

Proceed to Section V-ELECTRICAL

CONNECTIONS |

|

|

|

|

|

|

|

|

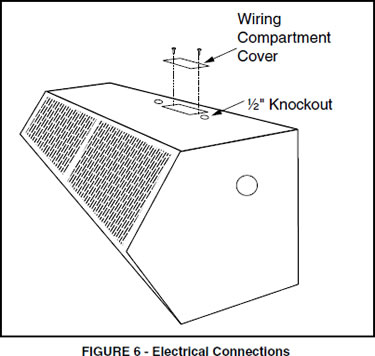

| V.

ELECTRICAL CONNECTIONS |

|

All

electrical wiring and connections MUST be per-

formed by qualified personnel in accordance with the

National Electrical Code ANSI/NFPA No. 70 (latest

edition) or, in Canada, the Canadian Electrical Code,

Part 1-C.S.A. Standard C22.1 and local codes and

regulations. |

|

|

|

|

|

|

| A.

Check the electrical rating nameplate on the top |

|

|

|

|

|

|

of the air curtain

for supply voltage and current

requirements. A separate line voltage supply with

a suitable branch circuit protection device should

be run directly from the main electrical panel to the

air curtain. A disconnect switch for each branch

circuit is a required part of this installation. |

|

|

|

|

| B.

All field wiring must be copper with a minimum |

|

|

insulation of

60° C within approved conduit. If any

of the wire supplied with the air curtain must be

replaced, it must be replaced with copper wiring

with a minimum insulation of 90° C. |

|

|

|

|

| C.

Remove the wiring tray cover; on air curtains that |

|

|

are comprised

of modules, remove the wiring tray

cover that is located closest to the electrical rating

nameplate (if it has not already been done).

See FIGURE 6. |

|

|

|

|

| D.

The top of the air curtain has two knockouts on |

|

|

each

side of the air curtain, allowing for a left hand

or right hand power connection. Remove the

required knockout if it has not already been done

and connect the power supply to the air curtain.

Connect all supply and control circuit wires

according to the wiring diagram provided. |

|

|

|

|

|

|

|

VII.

OPERATING INSTRUCTIONS |

|

|

|

|

|

|

A.

GENERAL OPERATION |

|

NOTE:

For Electrically Heated air curtain(s) provided

with the optional remote thermostat: mount and wire

the thermostat according to instructions and wiring

diagram. |

|

|

|

|

|

|

|

|

1. The air curtain

can be directly operated by using |

|

|

|

|

the

rocker switches located on the bottom of the

unit. The air curtain may also be automatically

operated by a combination of the rocker switches

and a remote door switch and/or thermostat

(See the wiring diagram). |

| VI.

MECHANICAL CONNECTIONS |

|

|

| A.

ELECTRICALLY HEATED MODELS |

|

|

|

The

heater circuit may be controlled by a combination

of a remote thermostat and the fan/off/fan & heat

rocker switch. Overheating protection is provided

by auto reset thermal cutouts built into the heater coil

assembly (see the wiring diagram, located in

wiring tray). |

|

|

|

|

|

|

|

|

2.

Rocker switch positions are labeled on the air

curtain cabinet. |

|

|

|

|

|

|

3.

Unheated units have one rocker switch that turns

the unit on or off. The other rocker switch selects

fan speed. |

|

|

|

|

|

|

|

|

|

|

|

4.

Heated units have one rocker switch that |

|

|

|

|

determines whether

the unit is off, energizes only

the fans, or energizes both the fans and the

method of heat. The other rocker switch selects

fan speed. |

|

|

|

|

|

|

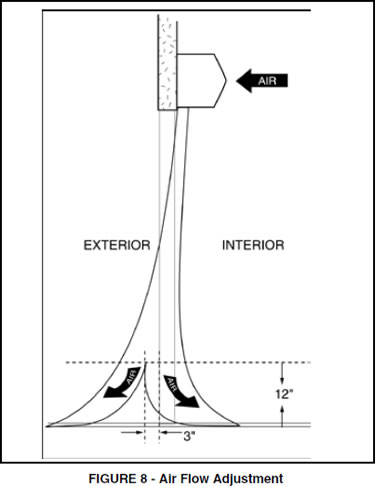

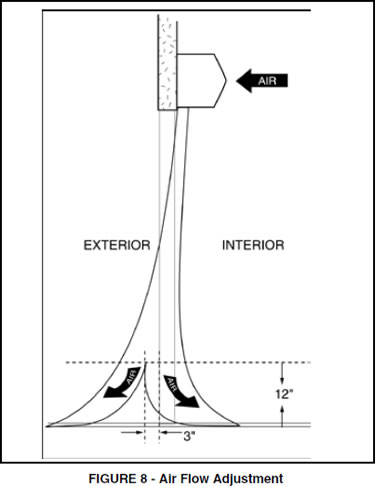

B.

AIR STREAM SPLIT ADJUSTMENT |

|

|

1.

With the air curtain operating and the door in its |

|

|

|

full open position,

check to see that nothing is

obstructing the air flow at the discharge nozzle

vanes. |

|

|

|

|

|

|

2.

Find the air stream split location. Hold a handker- |

|

|

|

chief, by its

corners, approximately 12” above

the floor. Gently move the handkerchief back

and forth in the doorway. Make sure the air is

being directed to both the inside and the outside.

The split location is indicated where the handker-

chief is vertical with minimal or no fluttering.

See FIGURE 8. |

|

|

|

|

|

|

3.

Adjust the discharge nozzle vanes so the split |

|

|

|

location is approximately

3” outside the doorway.

This is accomplished by first de-energizing the unit.

Remove the cover housing, loosen the nozzle vane

locking screws and adjust vanes. |

|

|

|

|

|

|

|

|

|

| VIII.

MAINTENANCE AND CLEANING |

|

|

|

CAUTION:

ELECTRIC SHOCK HAZARD Disconnect power

whenever servicing air curtain unit. More than one disconnect

may be required to de-energize air curtain unit. |

|

|

|

|

|

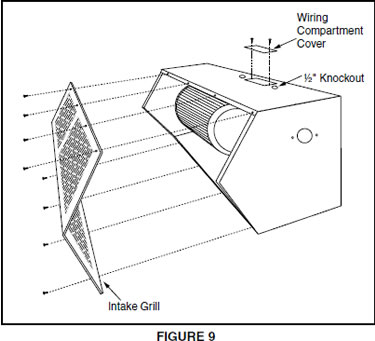

Keep

your air curtain operating at peak efficiency by

cleaning the blower wheels, motor(s) and intake grille.

Buildup of dust on the blower wheels can cause vi-

bration, noise and excessive wear on the motor

bearings. The frequency of cleaning will depend on

the environment in which the unit is operating. |

|

|

|

|

|

Dirty,

dusty or greasy environments could require a

cleaning schedule of once every two months. If the

environment is not that dirty, the unit(s) should be

scheduled for cleaning a minimum of once every

(6) months. To access the interior of the unit: |

|

|

|

|

|

| A.

Disconnect the power to the unit. |

|

|

|

|

|

B.

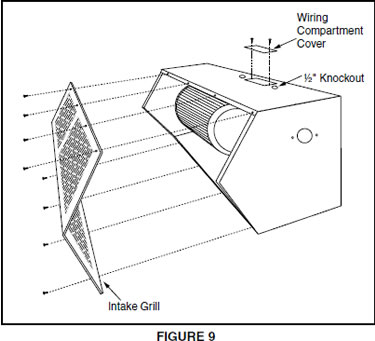

Remove the intake grille by removing all phillips head

screws around edge. See FIGURE 9. |

|

|

|

|

|

|

|

|

| C.

Vacuum and scrape (if necessary) to remove the |

|

|

|

|

buildup of dirt

and debris. The motor(s) are per-

manently lubricated and require no additional lu-

brication. Reinstall the cover and intake grille. |

|

|

|

|

|

|

|

| D.

Reconnect the power, and turn on after cleaning. |

|

|

|

|

CAUTION:

STAND CLEAR OF THE UNIT OR WEAR

SAFETY GOGGLES AS LOOSE DEBRIS MAY BE

PRESENT AND MAY EXIT THROUGH THE NOZZLE. |

|

|

|

|

|

A.

FAN AND MOTOR REMOVAL |

| IX.

SERVICE |

|

|

|

|

|

|

|

1.

Disconnect power to the unit. |

|

CAUTION:

ELECTRIC SHOCK HAZARD

Disconnect power whenever servicing air curtain unit.

More than one disconnect may be required to de-

energize unit. |

|

|

|

|

|

|

|

|

|

|

2.

Remove the intake grille by removing all phillips

head screws around edge. See FIGURE 9. |

|

|

|

|

|

|

|

|

3.

Unplug motor harness from motor and remove

necessary wiring. |

|

|

|

|

|

Any

service performed on the Certified Low Profile7/Commercial Low Profile 8

air

curtain MUST be done by qualified personnel. |

|

|

|

|

|

|

|

|

|

|

4.

Using a 1/8” Allen wrench, loosen each set screw

attaching fan(s) to motor. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.

While holding the motor in place, loosen and

remove the motor clips. |

|

Our

air curtains require very little servicing. All parts

are easily accessible for periodic inspection and

maintenance. Units should be cleaned at least twice

a year. Your particular application (the amount of dirt

and dust in the air) and location of the unit(s) will

determine how often your unit(s) will need to be

cleaned and serviced. All motors have permanently

lubricated, sealed, sleeve bearings and require no

maintenance. |

|

|

|

|

|

|

|

|

|

|

6.

Slide the fans toward the motor so that the ball

bearings on the outer fan shaft are exposed. |

|

|

|

|

|

|

|

|

7.

Slowly roll the motor out of the motor mount cradle |

|

|

|

|

forward and down.

The hubs of the fans are flexible

enough to allow the motor to move before the fans’

outer ball bearings pull out of the unit. |

|

|

|

|

|

|

Low Profile 8 Ambient Air

Curtains, Air Curtains, Commercial Air Curtain, Commercial Air Door, Unheated

Air Curtains,

and Insect Barrier from your source for material handling equipment. |

|

Back

to Product Category |

|

|