|

ENGINEERED

STEEL PRODUCTS |

| Priced

Full Line Products Catalog |

20

Technology Way • West Greenwich, RI 02817

Toll free:(800) 421-0314 • In RI:(401) 272-4570 • Fax:(401)

421-5679 |

|

|

|

|

Back

to Product Category

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjust-A-Link

slings should not be used at angles of less than 45°. |

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~ Add

items to your online shopping cart ~

Click a Price of the item you wish to purchase. |

|

|

|

|

|

|

PRICING

FOR ADJUST-A-LINK CHAIN SLINGS |

Size

and

Reach |

Part

No. |

Rated

Capacity* (lbs) |

Master

Plate Dimensions (in.) |

Wt.

(lbs.) |

PRICES |

Chain

Slings |

Chain

Slings

w/Latch |

| Single @90° |

Double @60° |

Eye

Width A |

Eye

Height B |

Overall

Width C |

Overall

Length D |

| 7/32" x 6 ft. |

30001G10 |

2,700 |

4,700 |

2.19 |

2.69 |

3.94 |

5.13 |

4.2 |

|

|

| 7/32" x 10 ft. |

30002G10 |

2,700 |

4,700 |

2.19 |

2.69 |

3.94 |

5.13 |

6.2 |

|

|

| 9/32" x 6 ft. |

30003G10 |

4,300 |

7,400 |

2.88 |

3.19 |

5.06 |

6.5 |

7.5 |

|

|

| 9/32" x 10 ft. |

30004G10 |

4,300 |

7,400 |

2.88 |

3.19 |

5.06 |

6.5 |

10.5 |

|

|

| 3/8" x 10 ft. |

30005G10 |

8,800 |

15,200 |

3.75 |

4.13 |

6.75 |

8.69 |

18.5 |

|

|

| 3/8" x 14 ft. |

30006G10 |

8,800 |

15,200 |

3.75 |

4.13 |

6.75 |

8.69 |

24.5 |

|

|

| 1/2" x 10 ft. |

30007 |

12,000 |

20,800 |

4.38 |

4.38 |

9.75 |

12.75 |

42 |

|

|

| 1/2" x 14 ft. |

30008 |

12,000 |

20,800 |

4.38 |

4.38 |

9.75 |

12.75 |

52 |

|

|

|

| *

1/2” size master link is flame cut, not forged; uses G80 capacity ratings. |

| Note:

For AAL w/latches, insert an L after the first 5 numbers in the part number.

Example: 30005LG10. |

|

|

|

|

* |

|

Do

not exceed rated capacities. Sling capacity decreases as the angle from

horizontal decreases.

Adjust-A-Link Slings should not be used at angles of less than 45°.

Refer to chain chart and

Effect of Angle chart below. |

|

|

|

|

|

|

HOOK DIMENSIONS (in.) |

|

Chain

Size

(in.) |

E |

F |

G |

H |

J |

K |

l |

7/32 |

0.85 |

3.78 |

2.62 |

2.69 |

0.55 |

0.872 |

0.30 |

9/32 |

1.01 |

4.41 |

3.01 |

3.19 |

0.64 |

1.03 |

0.37 |

3/8 |

1.44 |

6.66 |

4.77 |

4.33 |

0.91 |

1.30 |

0.58 |

1/2* |

1.78 |

8.16 |

5.69 |

5.50 |

1.13 |

1.66 |

0.75 |

|

| *1/2”

size master link is flame cut, not forged; uses G80 capacity ratings. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

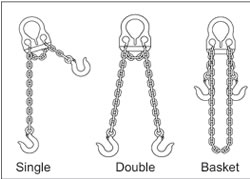

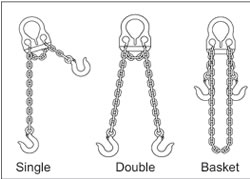

CHAIN SLING BASICS

|

|

|

|

|

|

|

|

|

| LiftAlloy

Grade 100 |

|

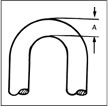

Chain

Wear Allowance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

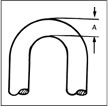

Determine

wear by measuring cross section at link

ends. If worn to less than the minimum thickness

allowable, chain should be removed from service. |

|

Available in sizes 7/32" through 3/4". Available in sizes 7/32" through 3/4".

Higher capacity

per chain size can be used as an Higher capacity

per chain size can be used as an

increased safety factor.

Higher capacity

may allow use of smaller diameter Higher capacity

may allow use of smaller diameter

chain for your lifts, reducing sling weight and cost.

Extreme abrasion

resistance - more durable. Extreme abrasion

resistance - more durable.

Powder-coated attachments

for corrosion resistance. Powder-coated attachments

for corrosion resistance. |

|

|

|

|

|

|

|

|

|

|

Minimum

thickness

based on OSHA

recommendations. |

|

|

|

|

|

|

|

|

|

|

|

|

| LiftAlloy

Grade 80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Available in sizes 7/8" through 1-1/4". Available in sizes 7/8" through 1-1/4".

Greater temperature

tolerance. Greater temperature

tolerance. |

|

|

|

|

|

|

Chain

Size (in.) |

Min.

Allowable

Thickness - A (in.) |

7/32 |

0.189 |

9/32 |

0.239 |

3/8 |

0.342 |

1/2 |

0.443 |

5/8 |

0.546 |

3/4 |

0.687 |

7/8 |

0.75 |

1 |

0.887 |

1-1/4 |

1.091 |

|

|

|

|

|

|

|

| All

Chain Slings |

|

|

|

|

|

|

|

|

Meet or exceed all OSHA, ASTM and NACM standards. Meet or exceed all OSHA, ASTM and NACM standards.

Welded or mechanically

assembled. Welded or mechanically

assembled. |

|

|

|

|

|

|

|

| ¹Rated

Capacity Chart for LiftAlloy Chain Slings |

Size of

Chain |

|

|

|

|

|

|

|

Nominal

Dim. (in.) |

Approx.

no. of

Links

per ft. |

Approx.

Weight

per

100 ft.

(lbs.) |

| (In.) |

(mm) |

Single

Chain @

90º (lbs.) |

Double Chain

Slings* (lbs.) |

Triple & Quad Chain

Slings* (lbs.)** |

Inside

Length |

Inside

Width |

| Grade 100 |

| 7/32 |

5.5 |

2,100 |

3,600 |

3,000 |

2,100 |

5,450 |

4,450 |

3,150 |

0.671 |

0.296 |

17.9 |

45 |

| 9/32 |

7.0 |

3,500 |

6,100 |

4,900 |

3,500 |

9,100 |

7,400 |

5,200 |

0.868 |

0.395 |

13.8 |

74 |

| 3/8 |

10.0 |

7,100 |

12,300 |

10,000 |

7,100 |

18,400 |

15,100 |

10,600 |

1.222 |

0.572 |

9.8 |

146 |

| 1/2 |

13.0 |

12,000 |

20,800 |

17,000 |

12,000 |

31,200 |

25,500 |

18,000 |

1.404 |

0.720 |

8.5 |

258 |

| 5/8 |

16.0 |

18,100 |

31,300 |

25,600 |

18,100 |

47,000 |

38,400 |

27,100 |

1.733 |

0.854 |

6.9 |

387 |

| 3/4 |

20.0 |

28,300 |

49,000 |

40,000 |

28,300 |

73,500 |

60,000 |

42,400 |

2.160 |

1.052 |

5.5 |

622 |

| Grade

80 |

| 7/8 |

22.0 |

34,200 |

59,200 |

48,400 |

34,200 |

88,900 |

72,500 |

51,300 |

2.250 |

1.137 |

5.3 |

776 |

| 1 |

26.0 |

47,700 |

82,600 |

67,400 |

47,700 |

123,900 |

101,200 |

71,500 |

2.664 |

1.348 |

4.5 |

995 |

| 1 1/4 |

32.0 |

72,300 |

125,200 |

102,200 |

72,300 |

187,800 |

153,400 |

108,400 |

3.250 |

1.656 |

3.7 |

1,571 |

|

| ¹

Rated Capacity also referred to as Working Load Limit. |

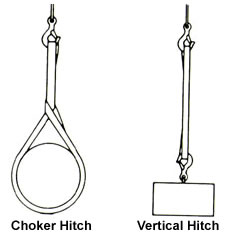

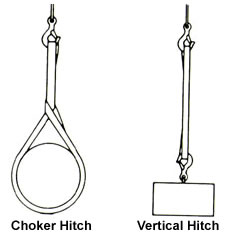

| When

using chain slings in a choke hitch, reduce the sling’s rated capacity

by 20% |

|

** A Quad Chain Sling may not sustain the load evenly on each of its'

four legs. The maximum working load

limits are therefore set at the same values as the Triple Chain Slings of

equal quality and size, and used with

branches at the same angle of inclinations. |

|

|

|

* |

|

Do

not exceed rated capacities. Sling capacity decreases as the angle from

horizontal decreases.

Adjust-A-Link Slings should not be used at angles of less than 45°.

Refer to chain chart above

and Effect of Angle chart below. |

|

|

|

|

|

|

|

|

|

|

|

|

| EFFECT

OF SLING ANGLE |

|

|

|

|

|

|

|

|

|

Using

slings at an angle can become deadly if that angle is not taken into

consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as the angle

of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching 90°.

Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or the length

and height of the sling as rigged, you can

determine the properly rated sling for your lift. The Increased Tension

method provides the increased tension as a

function of the sling angle. Alternatively, the sling Reduced Capacity method

may be used to determine reduced lift

capacity for any angle. |

|

|

|

|

|

|

|

|

|

INCREASED

TENSION

Determine capacity

of sling needed |

|

REDUCED

CAPACITY

Calculate rating of each sling

rigged at this angle |

|

|

|

|

|

| 1.

Determine the load weight (LW). |

1.

Calculate the reduction factor (RF). |

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to

the corresponding number of the

Reduction Factor column. |

| 2.

Calculate the Tension Factor [TF]. |

|

|

a.

Determine the sling angle as mea-

sured from the horizontal, and the

corresponding tension factor (TF)

from the effect of angle chart. |

|

|

|

-OR- |

|

|

b.

Divide sling height* (H) by sling

length* (L). |

|

-OR- |

|

|

|

b.

Length* (L) divided by height*

(H) |

|

|

|

|

|

2.

Reduction factor (RF) x the sling’s

rated capacity for the type hitch that

will be used = sling’s reduced rating. |

|

|

|

|

|

|

|

|

|

|

|

|

3.

Determine the share of the load

applied to each sling leg (LW). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.

Multiply (LW) by (TF) to determine

the sling leg tension. The capacity of

the selected sling or sling leg must

meet the calculated tension value. |

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal plane

to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart |

|

|

|

|

Tension

Factor (TF) |

Angle From

Horizontal |

Reduction

Factor (RF) |

| 1.000 |

90º |

1.000 |

| 1.004 |

85º |

0.996 |

| 1.015 |

80º |

0.985 |

| 1.035 |

75º |

0.966 |

| 1.064 |

70º |

0.940 |

| 1.104 |

65º |

0.906 |

| 1.155 |

60º |

0.866 |

| 1.221 |

55º |

0.819 |

| 1.305 |

50º |

0.766 |

| 1.414 |

45º |

0.707 |

| 1.555 |

40º |

0.643 |

| 1.742 |

35º |

0.574 |

| 2.000 |

30º |

0.500 |

|

|

|

|

|

|

|

|

|

Example: |

|

|

|

Vertical

Choker rating of each sling:

6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667 |

|

|

|

|

| Example: |

|

|

|

Load

weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1000 lbs.

per sling |

|

Sling

capacity decreases as the angle

from horizontal decreases. Sling angles

of less than 30° are not recommended. |

|

|

Reduced

sling rating in this configuration

= .667 |

|

(RF)

x 6,000 lbs. = 4,000 lbs. of lifting

capacity per sling |

|

|

|

|

|

|

|

Adjust-A-Link Chain Slings,

Lifting Sling, Lift-All, Sling, Adjustable and Versatile Chain Sling,

Alloy Steel Master

Control Link, Grade 80 Alloy Chain, and Serialized for Traceability from

your source for material handling equipment. |

Back

to Product Category |

|

|